An electric water pump, especially 12V/24V brushless DC models, has revolutionized liquid transmission in automotive cooling systems and new energy vehicles. Powered by piezoelectric materials, these pumps offer precise control for applications like car engine cooling, turbocharger thermal management, and EV battery cooling.

Electric water pump is a new type of water pump that uses piezoelectric materials as the power device, completely realizes electronization from control to drive, and completely controls liquid transmission with electronic integrated system, so as to realize the adjustability and accuracy of liquid transmission. Electric water pump has the characteristics of flexible control, energy saving and convenient use. It is more and more widely used in traditional vehicles and new energy vehicles.

The electric water pump of new energy vehicles is a key component of the vehicle cooling system. It is usually a 12V or 24V Electric coolant pump. The brushless motor drives the impeller to rotate, which increases the liquid pressure and drives the circulation of water, coolant and other liquids, so as to realize the heat dissipation of coolant. The 12V electric coolant pump is critical for EV battery thermal management, maintaining optimal temperatures (15-35℃) to prevent thermal runaway and extend battery life. Shenpeng's P8008 model, with 49L/min flow, is designed specifically for new energy vehicle drive systems.

Automobile electric water pump is mainly used for vehicle preheating system, automobile engine cooling cycle, hydrogen fuel cell thermal management system, new energy vehicle drive system, electric vehicle battery cooling system, and cooling system of automobile, motorcycle, new energy vehicle, hybrid bus, RV, racing car, street car, etc.

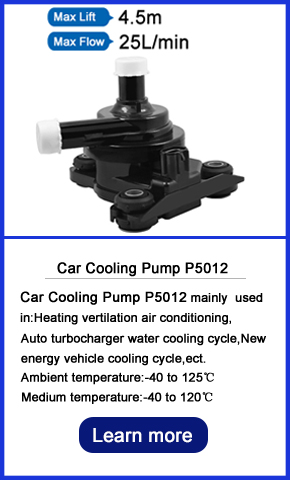

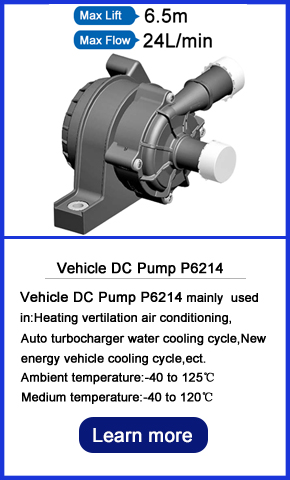

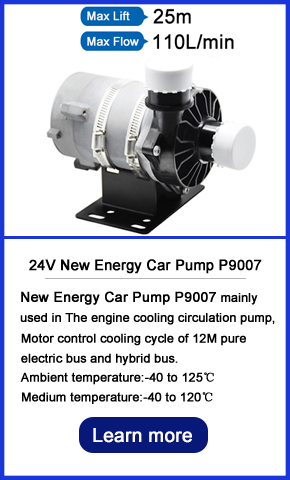

All standard Electric water pump by SHENPENG with lower price you will find here:

|  |  |

|  |  |

Want to learn more?

R & D, design and production of Electric water pump

Guangdong Shenpeng Technology Co., Ltd. was found in 2012 and is specialized in brush-less DC water pumps. As a global BLDC water pump solutions specialist, it integrates R&D, manufacture with sales.The products are mainly applied to New-energy vehicle, mattress, home appliance (water heater, dish washer, coffee machine, water dispenser), smart toilet, cosmetic/medical equipment, machine tool equipment, air conditioning base station, PC, LED cooling system etc.

Shenpeng was the earliest company that managed to produce the brushless DC water pumps. It is located in Changping, Dongguan and covers an area of 12000㎡. With an in-house CNAS standard laboratory, 300-thousand-grade dust-free workshop and 10 professional production lines. The annual production capacity is more than 5 million sets of water pumps and it is one of the largest manufacturer of BLDC water pump in China. It won many honorable titles such as High-tech Enterprise, Multiplication Enterprise etc. small electric water pump

What is an electric water pump?

An electric water pump is a specialized device designed to circulate coolant or water in various systems, replacing traditional engine-driven mechanical pumps. Unlike their mechanical counterparts, electric water pumps are powered by an electric motor, either brushless or brushed, enabling independent operation from the engine. This design offers precise control over flow rates, making them ideal for applications requiring variable cooling, such as automotive engine cooling, turbocharger thermal management, and new energy vehicle battery cooling systems. By separating from the engine’s rotational speed, electric water pumps enhance efficiency, reduce energy consumption, and enable intelligent thermal regulation.

How do electric water pumps work?

1. Working principle of automotive brushless electronic water pump

The brushless motor drives the impeller to rotate to increase the liquid pressure and drive the circulation of water, coolant and other liquids, so as to realize the heat dissipation of coolant.

The function of brushless electronic water pump in automobile:

Its main function is that during the operation of the car, the heat generated by a large amount of loss in the motor diffuses into the surrounding air through the surface of the motor, which will cause irreversible damage to electronic components. Therefore, usually, the outside of the motor will be covered with pipes containing water or coolant, and the excess heat will be taken away through the circulation of the water pump to ensure the normal operation of electronic components.

2. Working principle of automotive mechanical and electronic water pump:

It is the circular motion of the motor, which makes the diaphragm inside the water pump reciprocating through the mechanical device, so as to compress and stretch the air in the pump chamber (fixed volume), and form a positive pressure at the drain under the action of the one-way valve. A vacuum is formed at the pumping port, resulting in a pressure difference with the external atmospheric pressure. Under the action of pressure difference, the water pressure is fed into the water inlet and then discharged from the water outlet. Under the action of the kinetic energy transmitted by the motor, the water is continuously inhaled and discharged to form a relatively stable flow.

Role of automotive mechanical and electronic water pump:

The main function is to forcibly cool the engine oil at the turbine shaft after the car stalls. The outside of the turbine shaft of the lubrication and cooling system of the turbine is wrapped by oil. Since the oil inlet is much larger than the oil outlet, an oil film will be established between the turbine shaft and the shell under the action of oil pressure to lubricate the turbine shaft and take away part of the heat of the turbine (the heat taken by the oil is finally dissipated through the oil pan and oil cooler); The outside of the turbine shell in contact with the engine oil is wrapped by the cooling water. Similarly, since the water inlet is much larger than the water outlet, there will be a certain pressure on the cooling water between the shells here, but the function of this pressure is mainly to ensure that the cooling water is in good contact with the shell and obtain sufficient cooling effect.

The Role of Electric Water Pumps in Thermal Management

In thermal management systems, electric water pumps play a core role as the "power heart" and serve as key executive components for achieving efficient thermal management. Their essential function is to drive coolant circulation, providing continuous heat dissipation power for heating devices in fields such as new energy vehicles, energy storage systems, charging piles, and data centers. Similar to how the human heart pushes blood flow, electric water pumps propel coolant through components like motors, batteries, and power modules. The coolant absorbs heat and dissipates it through radiators, ensuring devices maintain suitable temperatures in harsh environments ranging from -40°C to 125°C.

Meanwhile, electric water pumps precisely regulate heat dissipation rates by collaborating with temperature sensors, ECUs, and other components. For example, in new energy vehicles, the ECU dynamically adjusts the pump speed based on battery temperature—reducing flow to accelerate heating at low temperatures and increasing flow to enhance cooling at high temperatures. This not only safeguards performance but also reduces energy consumption. Electric water pumps demonstrate multi-dimensional adaptability for different scenarios: resisting vibration and enduring extreme temperatures in new energy vehicles; requiring N+1 redundant designs and energy-saving frequency conversion in data centers; and emphasizing low noise and efficient heat dissipation in charging piles.

In terms of technological trends, intelligence (IoT monitoring), energy efficiency (rare-earth permanent magnet motors, energy recovery), and miniaturized integration (modular design) are driving their upgrading. In the future, with more precise temperature control capabilities, electric water pumps will become the core driving force for technological innovation in thermal management during the global energy transition and digitalization process. MORE>>

Technical requirements for electric water pumps

Flow demand: Determine the flow range of the water pump based on different vehicle models, battery capacity, and motor power. For example, the flow rate of the motor cooling pump for small pure electric vehicles is about 5-15L/min, and the flow rate of the battery cooling pump for large SUVs can reach 20-40L/min.

Head requirement: Based on the layout, length, and resistance of the cooling pipeline, calculate the required head of the water pump, which is generally between 5-20m, to ensure that the coolant can overcome resistance and circulate.

Temperature resistance performance: It needs to withstand extreme temperatures ranging from -40 ℃ to 125 ℃ to meet different working conditions of the vehicle in cold and hot regions. For example, the battery coolant pump needs to operate stably under high-temperature charging conditions for a long time.

Analysis of Type Adaptation of Electric Water Pump

Centrifugal electric water pump: With its high flow rate and medium head characteristics, it is suitable for cooling the main heat dissipation components such as motors and battery packs. For example, some BYD models use centrifugal water pumps to achieve efficient heat dissipation.

Diaphragm electric water pump: Due to its good sealing and ability to transport coolant containing impurities, it is commonly used in air conditioning systems and heating systems, effectively avoiding leaks and blockages.

Characteristics of electronic water pump

Electronic water pump is a new type of water pump, which uses piezoelectric materials as the power device, completely realizes electronization from control to drive, and completely controls liquid transmission with an electronic integrated system, so as to realize the adjustability and accuracy of liquid transmission. electric water pump camping

(1) The driving mode uses piezoelectric material as the power device, which subverts the traditional motor drive.

(2) It can accurately transport liquid and is used in liquid quantitative transmission, quantitative control and other fields.

(3) The speed of conveying liquid is adjustable. electric water pump for fish tank

(4) The pump body is equipped with an operation panel. All operations are completed through electronic buttons. All digital settings are equipped with digital display, which is intuitive and accurate.

(5) Small size and light weight. electric water pump submersible

The advent of the electronic water pump will bring the micro water pump industry into a new era. It is a new reform of the micro water pump industry and has far-reaching significance in the development history of the micro water pump industry.

Application of electric water pump technology in internal combustion engine

(1) Application of main cooling water pump of internal combustion engine.

The speed of the electric water pump is no longer directly related to the engine. The electronic control unit (ECU) collects parameters such as engine speed, load and water temperature through the sensor and compares them with the optimal water temperature under the calibrated corresponding working conditions, so as to control the speed of the water pump and realize the closed-loop control of liquid temperature. Its advantage is that the working temperature of the engine can be controlled in the best range, so as to improve the thermal efficiency of the engine and reduce fuel consumption, and realize the rapid warm-up under low temperature conditions. The speed of the electric water pump is controlled independently. Under the condition of non maximum cooling demand, it does not need full power operation. The maximum power and average power of the electric water pump are much lower than those of the mechanical water pump.

The power of the electric water pump is mainly distributed in 200 ~ 600 W. for vehicles equipped with ordinary generators and ordinary 12 V batteries, the power consumption and current in this power section are still too large. The electric energy driving the water pump is generated by the generator driven by the engine, and the multi-stage conversion of energy brings great efficiency loss. Because the electric water pump involves many fields of technology such as electronics, software, motor and hydraulic machinery, it is difficult. The failure of the water pump will also lead to the serious consequences of engine damage, so its reliability is highly required.

(2) Application of electric water pump in turbocharger cooling circuit.

Due to the contact with high-temperature exhaust gas and high-speed rotation of the turbocharger, the temperature at the turbine end will reach more than 600 ℃, while the working temperature of the sealing ring needs to be controlled below 230 ℃, and the bearing needs to be controlled below 150 ℃, otherwise the turbocharger will be damaged quickly, so effective cooling is the key. The turbocharger is generally designed with a liquid cooling circuit, but after the engine is shut down, the mechanical main water pump will also stop working. There is no cooling of circulating liquid, and the hot immersion will cause damage to the turbocharger bearing, shaft and seal. In order to solve this problem, a 15 ~ 30 # w auxiliary electric water pump is generally configured in the turbocharger cooling circuit to continue to provide cooling for the turbocharger after the engine is shut down.

(3) Application of electric water pump in intake intercooling circuit.

Due to the high-temperature heat conduction at the turbocharger turbine end and the heat generated by air compression, the air temperature after passing through the turbocharger compressor can reach 150 ℃, while the air temperature entering the engine should generally be controlled below 50 ℃, which requires cooling the pressurized air. At present, the mainstream technology adopts liquid cooling and air cooling to cool the intake air. In a supercharged engine equipped with a mechanical main water pump, a small electric water pump of 30 ~ 60 W is often configured in the liquid cooling circuit of the intercooler to control the intake air temperature. The use of electric water pump in intake intercooling system can solve the cooling demand of turbocharger through pipeline arrangement. In engines using external exhaust gas recirculation (EGR) technology, the liquid cooling circuit of EGR cooler is generally connected in parallel with the intake intercooling circuit to realize exhaust gas cooling.

(4) Thermal management system of internal combustion engine based on electric water pump.

After the engine uses the electric main water pump, it can realize the shutdown cooling function. On this basis, the thermal management system is equipped with an electronic control valve group that can control the flow direction and flow of the cooling circuit to match the needs of each cooling circuit. Without multiple water pumps, it can better meet the needs of thermal management of each part of the engine. At present, GM has used this technology in CSS series new engines. However, its thermal management system and electric water pump are designed and arranged separately and connected through pipelines. The integrated design of pump and valve can save the installation pipeline, optimize the layout space and reduce the pipeline interface, which is conducive to the reduction of cost, which may become the development trend of engine thermal management technology in the future.

Analysis of Typical Application Cases of Electric Water Pumps in New Energy Vehicles

1. Tesla Model Series: Intelligent Thermal Management Innovation with Electric Water Pumps

Tesla's Model series employs a strategy of collaborative operation by multiple electric water pumps to achieve zoned cooling for batteries and motors. In battery thermal management, the battery pack is divided into multiple independent cooling zones through the arrangement of multiple electric water pumps. Each zone's electric water pump can precisely adjust the coolant flow based on real-time temperature data from the battery modules. For example, when the vehicle is in fast-charging mode, some areas of the battery pack generate high heat due to high-current charging. At this time, the corresponding zone's electric water pump automatically increases its rotation speed to enhance coolant flow, quickly dissipating excess heat, ensuring temperature uniformity of the battery pack, and avoiding the impact of local overheating on battery life and performance.

In the motor cooling system, electric water pumps also play a key role. Tesla's high-performance motors generate significant heat under high-load operation, and the electric water pumps can dynamically adjust the coolant circulation rate based on the motor's working status and feedback from temperature sensors. Under intense driving or high-speed conditions, the electric water pumps increase flow to strengthen heat dissipation, ensuring the motor always operates within an efficient and safe temperature range, thus maintaining the motor's high-performance output and improving the vehicle's power performance and range capability.

Furthermore, Tesla uses software algorithms for intelligent control of electric water pumps. By integrating multi-dimensional data such as vehicle navigation information, driving modes, and ambient temperature, it pre-emptively predicts thermal management needs and optimizes the working status of electric water pumps. For instance, when vehicle navigation indicates an upcoming congested section, the system pre-emptively reduces the workload of electric water pumps to save energy; when approaching a Supercharger station, the system activates the electric water pumps to pre-cool the battery, preparing for fast charging and improving charging efficiency. This intelligent control strategy not only enhances the efficiency of the thermal management system but also further reduces vehicle energy consumption and extends the driving range.

2. BYD New Energy Models: Electric Water Pumps Empowering Efficient Thermal Management

The successful application of BYD's Blade Battery is inseparable from its advanced thermal management system, with electric water pumps serving as a key component. Aiming at the structural characteristics and heat dissipation requirements of the Blade Battery, BYD uses a dedicated electric water pump with high flow, high head, and excellent temperature resistance. During battery cooling, the electric water pump can quickly drive the coolant to circulate among battery modules, effectively dissipating heat generated during battery charging and discharging. Meanwhile, through precise control of coolant flow and direction, it achieves accurate regulation of battery temperature, ensuring the battery pack maintains an optimal working temperature range under various conditions, enhancing battery safety and stability.

In the thermal management of motors and electronic control systems, BYD's new energy models also adopt efficient electric water pump solutions. The electric water pumps closely coordinate with the cooling circuits of motors and electronic control systems, flexibly adjusting the coolant circulation speed according to heat generation under different working conditions. For example, in urban congested road conditions with frequent vehicle stops and starts, where the load on motors and electronic control systems changes significantly, the electric water pumps can promptly respond and adjust flow to ensure heat dissipation; during high-speed driving, the pumps maintain the system temperature stability in an optimal working state, reducing energy consumption.

Additionally, BYD emphasizes the collaborative optimization of electric water pumps with other thermal management components. Through linkage control with air conditioning and heating systems, it achieves rational heat distribution and recovery utilization. In winter, electric water pumps transfer waste heat from batteries and motors to the vehicle's heating system, which not only improves in-car comfort but also reduces additional heating energy consumption, further enhancing the vehicle's range capability. This integrated and intelligent thermal management solution fully demonstrates BYD's innovative strength in the field of new energy vehicle technology.

Key Role of Electric Water Pumps in Energy Storage Thermal Management

I. Coolant Circulation Drive: Constructing an Efficient Heat Dissipation Network

Energy storage systems primarily consist of key components such as battery modules, Power Conversion Systems (PCS), and energy storage cabinets, all of which generate significant heat during operation. Take lithium-ion batteries as an example: during high-rate charging and discharging, electrochemical reactions within the battery intensify, converting substantial electrical energy into heat. If heat is not dissipated in a timely manner, the battery temperature will rise rapidly, not only causing battery capacity degradation and shortened cycle life but also potentially triggering safety hazards such as thermal runaway. In the process of AC-DC power conversion in PCS, power devices like IGBT modules also generate substantial heat due to losses, affecting their power conversion efficiency and reliability.

Electric water pumps establish a closed coolant circulation loop, constructing an efficient heat dissipation network for energy storage systems. In practical operation, the electric water pump draws low-temperature coolant from the low-temperature end of the energy storage system (e.g., the cooling water tank or cooler outlet) and injects it into the cooling channels of heat-generating components such as battery modules and PCS. For example, in a large lithium battery energy storage power station, as the coolant flows through the cooling channels of the battery modules, it removes heat generated by the batteries through heat exchange, reducing the battery temperature; the coolant flowing through the PCS absorbs heat emitted by the power devices. The high-temperature coolant after heat absorption then flows back to the cooling water tank or cooler, dissipating heat to the external environment through air cooling, water cooling, or phase-change cooling, completing a full cycle. Repeating this process, the electric water pump continuously drives coolant circulation, ensuring that heat from each key component of the energy storage system is promptly removed and maintaining uniform and stable system temperatures.

It is worth noting that the circulation drive capability of electric water pumps directly influences heat dissipation efficiency. The flow rate and head parameters of the pump determine the flow velocity and range of the coolant in the system. For large-scale energy storage power stations, due to high heat dissipation requirements and long, complex pipelines, large-flow, high-head electric water pumps are needed to ensure that the coolant can quickly flow through each heat dissipation part for efficient heat dissipation. In small household energy storage devices, micro electric water pumps can also stably drive coolant circulation with their low-power consumption and compact size, meeting heat dissipation needs in confined spaces.

II. Precise Temperature Regulation: Achieving Intelligent Thermal Management

Different components of energy storage systems have varying sensitivities to temperature, and their heat generation conditions also differ under different operating conditions. For instance, charging batteries in low-temperature environments not only reduces charging efficiency but may also cause irreversible capacity loss; prolonged operation in high-temperature environments accelerates battery aging. Therefore, achieving precise temperature regulation for each part of the energy storage system is crucial.

Electric water pumps work in conjunction with temperature sensors and control systems to build an intelligent thermal management system. Temperature sensors are deployed at key positions in the energy storage system, such as the surface of battery cells in modules and near power devices in PCS, to monitor temperature changes in real time. The control system receives signals feedback from temperature sensors and compares and analyzes them with pre-set temperature thresholds. When the temperature of a part is detected to rise, the control system sends an instruction to the electric water pump to increase the coolant flow by raising the pump speed, thereby enhancing the heat dissipation capacity of that part and lowering the temperature; conversely, when the temperature drops to a certain level, the control system reduces the pump speed to decrease coolant flow and avoid energy waste caused by excessive cooling.

Take the flow battery energy storage system as an example: the electrolyte of the flow battery generates heat during redox reactions in the stack, resulting in uneven temperature distribution. By arranging temperature sensors in different areas of the stack, the control system can precisely control the operation of the electric water pump based on the temperature of each area, making the coolant preferentially flow to the higher-temperature areas to achieve precise temperature balance. Additionally, some advanced energy storage thermal management systems have introduced artificial intelligence algorithms, which predict the temperature change trend of the energy storage system by learning from and analyzing large amounts of operation data, adjusting the working state of the electric water pump in advance to further enhance the precision and timeliness of temperature regulation.

Electric water pumps assume the dual critical missions of coolant circulation drive and precise temperature regulation in energy storage thermal management. Their efficient and stable circulation drive capability constructs a reliable heat dissipation channel for energy storage systems, while their precise temperature regulation function ensures that energy storage systems maintain optimal operating temperatures under various conditions. With the continuous development of energy storage technology and the increasing richness of application scenarios, the requirements for the performance and intelligence level of electric water pumps will continue to rise. In the future, electric water pumps will develop towards higher efficiency, more precise control, and more intelligent collaboration, continuously escorting the efficient and stable operation of energy storage systems.

Application of electric water pump technology in new energy electric vehicles

The application of electric water pump in electric vehicle is mainly the liquid cooling circuit of driving system and the liquid cooling circuit of power battery. The drive system includes drive motor, motor controller and reducer. When the drive motor operates under heavy load, it will produce a lot of heat, and the high-power device IGBT in the motor controller will also generate a lot of heat. Too high temperature will lead to the decline of motor and electronic control efficiency, and out of control temperature will lead to the serious consequences of rapid burning. In order to ensure good lubrication in the high-speed reducer, it is also necessary to control the lubricating oil temperature through the heat exchanger. Therefore, the drive system is generally designed with a liquid cooling circuit, and its coolant temperature is generally required to be controlled within 90 ℃. The power of the electric water pump used in this system is generally 40 ~ 60 W.

The lithium-ion power battery of electric vehicle will generate heat during charging and discharging, especially during fast charging and high-power discharging, its optimal working temperature is 15 ~ 35 ℃, too low and too high temperature will reduce the charging and discharging performance and cycle life of the power battery, and thermal runaway can also lead to spontaneous combustion of the power battery. Therefore, the power batteries are designed with a thermal management system for liquid circulation. The liquid circulation circuit has a heat exchanger for heat exchange with the air conditioning system and an electric heater for heating the liquid. The electric water pump drives the liquid circulation flow to realize the heating and cooling of the power battery. The temperature of the power battery is controlled at 10 ~ 55 ℃, the temperature of the liquid in the battery thermal management system is generally lower than 50 ℃, and the power of the electric water pump is generally 50 ~ 120 W.

There are also chargers, inverters, DC transformers and other components in electric vehicles, which also need to use liquid cooling system. Due to the large difference in the temperature range between the driving system and the battery thermal management control, the same cooling system cannot be used, so more than two electric water pumps are generally used. The difference between the electric water pump for electric vehicle and the electric water pump for internal combustion engine is that the working medium temperature of the internal combustion engine water pump can reach 120 ℃ and the ambient temperature can reach 150 ℃, and its high-temperature reliability requirements are very high. In addition to working when the vehicle is running, the water pump of electric vehicle should also work during charging, and its service life is required to be higher.

In internal combustion engine, compared with mechanical water pump, electronic water pump has significant technical advantages. With the improvement of braking energy recovery and power generation efficiency, it can effectively solve the problem of power supply, so that the application of electronic water pump will become the mainstream trend. In order to solve the different temperature management requirements of turbocharger cooling and intake intercooling, the thermal management system based on electronic water pump has been applied, and the pump valve integration technology scheme may be the trend in the future. The technology of electronic water pump in electric vehicles is relatively mature, and its application has become a popular trend.

Information and troubleshooting methods to be mastered in case of Electric water pump failure.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117