Food Grade Pump: A Comprehensive Guide

Food grade pumps are specifically designed for handling fluids that come into direct contact with the human body, such as food, beverages, and pharmaceuticals. Compared with ordinary pumps, food-grade pumps have extremely strict requirements in terms of material selection and hygiene standards. Ordinary pumps focus on functionality and cost-effectiveness, and only consider corrosion resistance and mechanical strength when selecting materials; the core of food-grade pumps lies in ensuring that the fluid is not contaminated or chemically reactive during the transmission process, thus guaranteeing the safety and quality of the final product.

In terms of material application, all components of food-grade pumps that come into contact with the fluid, such as the pump body, impeller, and seals, are made of materials that meet food hygiene and safety standards. Common materials include food-grade plastics such as polypropylene (PP) and polyethylene (PE), which are non-toxic, odorless, and have high chemical stability, effectively preventing chemical reactions with the fluid; medical-grade stainless steels such as 304 and 316L are also commonly used materials. They not only have excellent corrosion resistance but also have a high surface finish, are less likely to breed bacteria, and are easy to clean and disinfect. In contrast, ordinary pumps may use common engineering plastics or industrial-grade metal materials, which pose a risk of material component leaching and fluid contamination during long-term contact with food and beverages.

In terms of structural design, food-grade pumps follow the principles of no dead corners and easy cleaning. Their internal flow channels are smoothly designed to avoid dead corner areas where liquid can accumulate; at the same time, the components are highly detachable, facilitating users to carry out in-depth cleaning and maintenance, reducing the growth of bacteria and the accumulation of dirt. Ordinary pumps rarely consider the convenience of cleaning and maintenance and are difficult to meet strict hygiene requirements when used for food and beverage transportation.

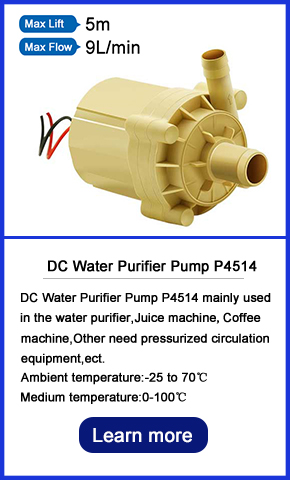

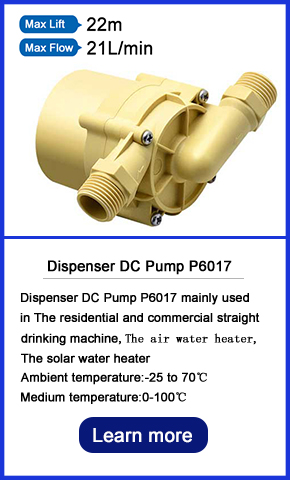

All standard Food grade pump by SHENPENG with lower price you will find here:

|  |  |

Want to learn more?

The working principle and importance of micro food grade water pumps

Micro food grade water pumps typically consist of the following basic components: pump body, pump cover, impeller, shaft, and sealing system. The pump body and pump cover constitute the outer shell of the pump, and the impeller is the core component of the pump, responsible for the transportation of liquids.

Startup phase: When the pump starts, the motor drives the shaft to rotate, which in turn drives the impeller to rotate.

Suction stage: The rotation of the impeller generates centrifugal force, causing the liquid to be sucked into the pump body.

Transport stage: The liquid is propelled by the impeller and transported along the pump's flow channel to the outlet.

Boosting stage: Due to the high-speed rotation of the impeller, the liquid gains kinetic energy inside the pump, thereby achieving boosting.

3. Types of micro food grade water pumps

Micro food grade water pumps can be classified into several types based on their working principles, including centrifugal pumps, gear pumps, screw pumps, etc. Each pump type has its specific application scenarios and advantages.

Characteristics of food grade pump products:

1. Flow and Head Characteristics

Food grade centrifugal pumps exhibit distinct characteristics in terms of flow and head. They offer a considerable and adjustable flow rate. Within the rated speed range, there is an approximate linear relationship between the flow rate and the rotational speed. Flow adjustment can be easily achieved by precisely controlling the motor speed through variable frequency technology or by skillfully adjusting the opening of the outlet valve. Compared with other types of pumps, food grade centrifugal pumps can stably deliver a larger flow rate under the same power condition, meeting diverse fluid conveying requirements. In terms of head performance, food grade centrifugal pumps are typically medium - low head pumps, with the head usually ranging from several tens of meters. This characteristic is determined by their working principle and structural design. As the head increases, the pump efficiency gradually decreases. Therefore, during actual selection and application, it is essential to accurately set the pump's operating point within the high - efficiency range according to specific working conditions to ensure optimal performance and energy utilization efficiency.

2. Suitable for Applications with Large Flow and Medium - Low Head

Thanks to their characteristics of large flow and medium - low head, food grade centrifugal pumps are widely used in household appliances and related fields. In water dispensers and water purifiers, to ensure the rapid and stable transportation of water from the storage end to various treatment processes such as filtration and heating, and finally to the user end, a high flow rate is required while the head to be overcome is relatively low. Food grade centrifugal pumps can precisely meet these needs, ensuring the efficient operation of water drinking equipment. During the production process of juicers, a large amount of pulp needs to be juiced quickly and the juice needs to be transported to the storage tank. The large flow characteristic of centrifugal pumps significantly improves the juicing efficiency. In the water inlet and drainage processes of dishwashers, it is necessary to quickly complete the injection of cleaning liquid and the discharge of sewage. With their large flow and appropriate head, food grade centrifugal pumps ensure the smooth and efficient operation of the dishwasher cleaning process, making them an ideal fluid conveying solution.

3.1 Advantages of DC Brushless Motor Drive

DC brushless food grade pumps equipped with DC brushless motors demonstrate outstanding driving performance. From an energy - saving perspective, traditional brushed motors have significant energy losses due to the friction between the carbon brushes and the commutator. In contrast, DC brushless motors adopt electronic commutation technology, completely eliminating this frictional loss, resulting in a substantial increase in motor efficiency. Compared with traditional brushed motor pumps, energy savings of 30% - 50% can be achieved, effectively reducing the full - life - cycle operating costs of the equipment. In terms of speed control, DC brushless motors achieve precise speed adjustment through Pulse Width Modulation (PWM) signals. They can flexibly control the speed within a wide range, thereby accurately adjusting the flow rate and pressure output of the pump. Whether the equipment is in a low - load standby state or facing high - load working requirements, it can respond quickly and maintain stable and efficient operation, easily adapting to complex and changeable working conditions.

3.2 Comparison with Traditional Brushed Motor Pumps

Compared with traditional brushed motor pumps, DC brushless food grade pumps have significant advantages in service life, noise, and electromagnetic interference. The carbon brushes of traditional brushed motors continue to wear during long - term operation. When the wear reaches a certain level, the carbon brushes must be replaced; otherwise, it will lead to motor failure. Their average service life is usually only 1000 - 3000 hours. DC brushless motors, however, abandon the carbon brush structure, and their main losses come from components such as bearings. Under normal working conditions, the service life can reach more than 10,000 hours, greatly reducing the frequency of equipment maintenance and downtime, and lowering the comprehensive maintenance cost. In terms of operating noise and electromagnetic interference, the friction between the carbon brushes and the commutator of traditional brushed motors generates significant noise, and the sparking during commutation creates electromagnetic interference, affecting the normal operation of surrounding electronic devices. DC brushless motors operate smoothly and quietly, generating almost no electromagnetic interference, creating a quiet and stable usage environment. They are more suitable for application scenarios with strict requirements for noise and electromagnetic environment.

3.3 Application Advantages in Specific Household Appliances

In the application scenario of juicers, DC brushless food grade pumps significantly enhance product quality with their excellent performance. Through precise speed control, the impeller can rotate at the optimal speed, quickly separating the pulp from the juice while minimizing damage to the juice cells, and completely preserving the nutrients such as vitamins and minerals, as well as the natural flavor substances in the juice. In addition, the efficient motor drive enables the pump to process a large amount of fruit in a short time, greatly improving the juicing efficiency and meeting users' rapid demand for fresh juice. In the field of dishwashers, DC brushless food grade pumps show strong environmental adaptability. When dishwashers are in operation, the internal environment is high - temperature and high - humidity. The motors of ordinary pumps are prone to failure due to the erosion of water vapor and high temperature. DC brushless motors adopt a fully sealed design, effectively isolating water vapor and heat, protecting the internal electronic components, and ensuring the stable operation of the pump in high - temperature and high - humidity environments. They provide reliable power support for the water inlet, drainage, and spray systems of dishwashers, ensuring efficient tableware cleaning results.

Application of food grade pumps in dishwashers

1. Key Roles of Pumps in Dishwasher Workflows

During the operation of a dishwasher, food-grade pumps play a crucial role in the three core processes of water inlet, drainage, and spraying, directly determining the overall operation efficiency and cleaning effect of the dishwasher. In the water inlet process, the pump needs to precisely control the water flow speed and volume, quickly injecting an appropriate amount of clean water into the dishwasher. This prevents delays in the washing cycle caused by slow water injection or the risk of overflow due to excessive water intake. When it comes to drainage, the pump must overcome pipeline resistance to thoroughly discharge the used washing water, avoiding the breeding of bacteria and the generation of odors from residual sewage, which could affect subsequent washing quality.

The spraying process is key to achieving efficient cleaning in dishwashers. The pump pressurizes the washing liquid and delivers it to the spray arms, which then eject it at high speed, creating a powerful water flow to scrub the surfaces of tableware. This process requires the pump to have a stable pressure output to ensure that tableware at all angles is uniformly and powerfully impacted by the water flow. To adapt to the high-temperature (up to 70℃ - 80℃) and high-humidity working environment of dishwashers, food-grade pumps are designed with special high-temperature and corrosion-resistant materials. For example, the pump housing is made of high-temperature-resistant engineering plastics, and the internal seals are made of fluororubber. These materials can withstand the erosion of high-temperature steam and effectively prevent leakage of the washing liquid, ensuring the long-term stable operation of the pump. Meanwhile, the motor part features waterproof and moisture-proof designs, combined with heat dissipation structures, to avoid motor failures caused by high temperature and humidity and extend the pump's service life.

2. Impact on Cleaning Effect and Energy Consumption

The flow rate and pressure parameters of the pump play a decisive role in the spraying intensity and cleaning degree of the dishwasher. A larger flow rate can provide an ample amount of washing liquid, ensuring that the surfaces of tableware are fully wetted. An appropriate pressure enables the spray arms to generate a water flow with sufficient impact force, effectively removing stubborn oil stains and food residues. For instance, when the pump pressure is insufficient, the impact force of the water flow weakens, making it difficult to thoroughly clean burnt stains on the bottom of pots and baking trays. If the flow rate is too low, some areas of the tableware may not be adequately washed, resulting in incomplete cleaning. Experimental data shows that, under the same washing program, dishwashers equipped with high-flow and high-pressure pumps achieve a cleaning degree improvement of approximately 20% - 30% compared to those with ordinary pumps.

In terms of energy consumption, high-efficiency and energy-saving pumps bring significant optimizations to dishwashers. Traditional dishwasher pumps have issues such as high energy loss and low efficiency during operation. In contrast, the new generation of food-grade DC brushless pumps adopt advanced motor drive technology. Through intelligent control algorithms, they dynamically adjust the rotation speed according to the requirements of different washing stages, avoiding unnecessary energy consumption. Take a dishwasher equipped with an energy-saving pump as an example; in the standard washing mode, its single-run energy consumption is reduced by about 15% - 20% compared to models using traditional pumps. Moreover, the efficient operation of energy-saving pumps reduces heat generation, eases the heat dissipation burden inside the dishwasher, and indirectly improves the overall energy efficiency ratio of the machine, aligning with the current market trend of energy conservation and environmental protection.

Application of food grade pumps in water dispensers

1. Water Supply and Circulation Functions of Pumps in Water Dispensers

In the operating system of a water dispenser, the pump plays a core role in water supply and circulation, and its performance is directly related to the water outlet effect and water quality guarantee of the water dispenser. The design to ensure a stable water outlet flow and water quality is an important responsibility of the pump in the water dispenser. To achieve a stable water outlet flow, the pump needs to have precise flow control capabilities. In terms of design, the uniformity of water flow output will be ensured by optimizing the impeller structure of the pump and the motor speed regulation mechanism. For example, a pump driven by a DC brushless motor can adjust the speed in real-time according to the water outlet demand of the water dispenser through precise electronic speed regulation, thereby stabilizing the flow. At the same time, in terms of water quality guarantee, the design of the pump must avoid polluting the water body. The smooth design of the flow channel can reduce water flow resistance, reduce the retention time of water in the pump, and reduce the possibility of bacterial growth. In addition, the layout of the flow channel in the part of the pump that contacts water is carefully planned to ensure that the water flow can pass through smoothly, avoiding dead corners, and further ensuring water quality.

Measures to prevent secondary pollution are closely related to the material requirements of the pump. In terms of measures to prevent secondary pollution, the sealing performance of the pump is crucial. The use of high-quality mechanical seals or food-grade seals can effectively prevent external air and impurities from entering the pump and contacting the water body, and at the same time prevent water leakage from causing pollution. In terms of material requirements, the parts of the pump that are in direct contact with water must be made of food-grade standard materials, such as 304 stainless steel, food-grade PP (polypropylene), etc. These materials have good corrosion resistance, non-toxicity, and will not release harmful substances into the water, ensuring drinking water safety.

2. Impact on Drinking Water Safety and Convenience

The reliability of the pump has a direct and key impact on the long-term use of the water dispenser. If the reliability of the pump is insufficient and failures occur frequently, it may cause the water dispenser to fail to supply water normally. During maintenance, users cannot obtain drinking water in time, affecting daily life. What's more, failures may cause water leakage. If the leaked water comes into contact with the electrical components inside the water dispenser, there will also be potential safety hazards such as short circuits and electric shocks. In addition, the unstable operation of the pump may cause water flow fluctuations, which in turn affect the filtration system of the water dispenser. For example, fluctuating water flow may make the filtration effect of the filter element unstable, failing to effectively remove impurities, bacteria and other harmful substances in the water, threatening drinking water safety. A highly reliable pump, on the other hand, can operate stably for a long time, ensuring that the water dispenser continuously and normally provides drinking water that meets safety standards, and reducing safety risks and inconvenience caused by pump failures.

Intelligently controlled pumps have brought significant improvements in energy saving and user experience. In terms of energy saving, the intelligently controlled pump can automatically adjust the operating power according to the actual water consumption of the water dispenser. When users do not need a large amount of water, the pump will reduce the speed to reduce energy consumption; during peak water consumption, it will automatically increase the power to meet the water demand. This on-demand adjustment method can save a lot of electricity compared with traditional pumps that run at a fixed power. For example, during nighttime or periods of non-use, the intelligent pump can enter a low-power standby mode, greatly reducing energy consumption. In terms of user experience, the intelligently controlled pump can achieve more precise water outlet control. Users can set the water output through the control panel of the water dispenser, and the pump will accurately output the corresponding amount of water according to the setting, avoiding waste of water resources. At the same time, some intelligent pumps also have a water shortage reminder function. When the water level in the water dispenser tank is insufficient, it will automatically issue an alarm and stop running to prevent the pump from idling and being damaged, and also facilitate users to add water in time. In addition, the intelligent pump runs with lower noise, creating a quiet living environment for users and further improving the user experience.

Application of food grade pumps in water purifiers

Water purifiers, as key equipment for ensuring the safety of drinking water in households and commercial places, rely highly on the collaborative work of internal components for their core functions. Among these, food grade pumps play an indispensable role. Whether it is the extraction of raw water, the maintenance of pressure during the filtration process, or the delivery of purified water, the performance of the pump directly affects the overall operation effect and water quality of the water purifier. Next, we will delve into the specific applications of food grade pumps in water purifiers.

1. The Role of Pumps in the Filtration and Water Production Process of Water Purifiers

In the filtration and water production process of water purifiers, the pump is like a "heart" that provides power support for the entire water circulation system, ensuring that water can complete a series of purification treatments according to the preset path.

Providing sufficient pressure to drive water through the filter elements is one of the core functions of the pump. The filtration system of a water purifier usually consists of multiple stages of filter elements, such as pre-activated carbon filter elements, RO reverse osmosis membranes, and post-activated carbon filter elements. For water to pass through these filter elements smoothly, especially the RO reverse osmosis membrane with extremely small pores, it needs to overcome the resistance of the filter elements themselves. Without sufficient pressure, the water flow rate will become extremely slow, or even unable to pass through the filter elements, resulting in the water purifier being unable to produce water normally. However, food grade pumps can provide stable and sufficient pressure to push raw water through each stage of filter elements in sequence, so that impurities and pollutants in the water are effectively filtered out, thereby obtaining clean water that meets the standards.

At the same time, the pump also needs to meet the working requirements of different filtration technologies (such as RO reverse osmosis, ultrafiltration, etc.). For RO reverse osmosis filtration technology, it has high requirements for inlet water pressure. Generally, a pressure of 0.4-0.6MPa is required to achieve an effective reverse osmosis process, intercepting harmful substances such as dissolved salts and heavy metals in the water. At this time, the pump needs to accurately provide this pressure range to ensure the filtration efficiency and effect of the RO membrane. Ultrafiltration technology has relatively lower pressure requirements. The pump needs to adjust the output pressure to adapt to the working characteristics of the ultrafiltration membrane, avoid damaging the ultrafiltration membrane due to excessive pressure, and ensure that water can pass through smoothly to filter macromolecular impurities and colloids in the water.

2. Impact on Water Purification Effect and Filter Element Lifespan

The pressure stability of the pump has a direct impact on the filtration accuracy of the filter element. Take the RO reverse osmosis filter element as an example, it has extremely high filtration accuracy and can remove most pollutants in the water. But this high-precision filtration depends on stable inlet water pressure. If the pressure provided by the pump fluctuates, it will cause the working state of the RO membrane to be unstable. When the pressure is too high, some pollutants may "break through" the interception of the membrane and enter the purified water, reducing the filtration accuracy; when the pressure is too low, it cannot effectively push the water through the membrane, which not only affects the water production efficiency but also may cause the accumulation of pollutants on the membrane surface, which will affect the filtration effect in the long run. For ultrafiltration filter elements, unstable pressure will also affect their interception effect on macromolecular substances, leading to fluctuations in the quality of purified water. Only when the pump can provide stable pressure can the filter element always operate in the best working state, ensuring filtration accuracy and thus obtaining high-quality purified water.

An appropriate pump flow rate can significantly extend the service life of the filter element. The service life of the filter element is closely related to the water flow rate and the amount of water passing through it. If the pump flow rate is too large, exceeding the bearing capacity of the filter element, the impact force of the water flow on the filter element will increase, accelerating the wear and aging of the filter element material. At the same time, a large flow rate will cause more pollutants to be intercepted on the surface and inside the filter element in a short time, making the filter element reach a saturated state faster and requiring frequent replacement. On the contrary, if the pump flow rate is too small, although the impact force on the filter element is reduced, the water flow stays in the filter element for too long, which may cause the intercepted pollutants to dissolve into the water again, affecting the purification effect, and the too small flow rate will also reduce the water production efficiency. Therefore, choosing a pump flow rate that matches the characteristics of the filter element can make the water flow pass through the filter element at a reasonable speed, ensuring the purification effect while reducing the loss of the filter element, thereby extending the service life of the filter element and reducing the user's use cost.

3. Case Analysis: Pump Selection and Technology of Well-known Water Purifier Brands

A certain brand of RO reverse osmosis water purifier is widely praised in the market for its high quality and stable performance, and its pump selection is quite particular. This brand uses a DC brushless food grade pump specially designed for RO reverse osmosis water purifiers. This pump has the following significant advantages: Firstly, it has extremely high pressure control accuracy and can stably output a pressure of about 0.5MPa, which fully meets the working needs of the RO reverse osmosis membrane, ensures the stability of filtration accuracy, and keeps the quality of purified water at an excellent level. Secondly, the flow adjustment range is wide, which can be accurately adjusted according to different usage scenarios and filter element states, avoiding loss to the filter element due to improper flow. Moreover, it is made of food-grade materials, and the parts in contact with water meet international standards such as FDA, ensuring the safety of purified water and no secondary pollution to water quality. In addition, the pump has high operating efficiency and low energy consumption, effectively reducing the overall energy consumption of the water purifier while providing strong power.

The technical upgrading of this pump has promoted the overall performance of the brand's water purifier in many aspects. In terms of water production efficiency, due to the stable pressure and reasonable flow rate of the pump, the water production speed of the water purifier has increased by about 30% compared with traditional products, greatly shortening the user's waiting time. In terms of energy saving, the application of DC brushless motors has reduced the energy consumption of the pump by more than 20%. Combined with intelligent control technology, when the water purifier is in standby mode, the pump can automatically enter a low-power mode to further save energy. In terms of service life, precise pressure and flow control have reduced the loss of core filter elements such as RO reverse osmosis membranes, extending the replacement cycle of filter elements by about 50%, which not only reduces the user's use cost but also reduces the generation of waste, making it more environmentally friendly. At the same time, the pump operates with extremely low noise. By optimizing the internal structure and using noise-reducing materials, the noise during operation is controlled below 40 decibels, improving the user's experience. It is precisely because of the application of this high-performance pump that the brand's RO reverse osmosis water purifier has an obvious advantage in the market competition and has won the favor of the majority of consumers.

Application of food grade pumps in water boilers

1. Heating and Water Supply Control of Pumps in Water Boilers

In the operation process of water boilers, the pump plays a crucial role, and its coordinated work of heating and water supply control as well as its ability to adapt to high-temperature environments directly affect the performance and reliability of the water boiler.

The precise control of the coordinated work between water flow and heating power is the core of the efficient operation of the water boiler. The working principle of a water boiler is to heat water to boiling through heating elements, while the pump is responsible for delivering cold water to the heating chamber and transporting hot water to the outlet at the right time. To achieve precise control of this process, advanced water boilers adopt an intelligent control system, which can adjust the water flow rate and heating power of the pump in real time according to the set temperature and water demand. For example, when users need a small amount of boiling water, the control system will instruct the pump to supply water at a lower flow rate and reduce the heating power at the same time to avoid energy waste; when there is a large demand for water, the pump will increase the water flow rate and the heating power will also increase accordingly, so as to ensure that boiling water meeting the temperature requirements can be provided quickly under different water consumption situations. This coordinated working mode not only improves the use efficiency of the water boiler but also effectively avoids problems such as unstable water temperature or excessive energy loss caused by mismatched water flow and heating.

The pump body materials and sealing technology adapted to high-temperature environments are key to ensuring the long-term stable operation of the water boiler. The water temperature inside the water boiler usually reaches around 100°C. Being in such a high-temperature environment for a long time, the pump body materials and sealing components are faced with severe tests. In terms of pump body material selection, food-grade stainless steel (such as 304, 316L) or special engineering plastics with high-temperature resistance are usually used. These materials have excellent high-temperature resistance, can maintain stable physical and chemical properties at high temperatures, will not deform, age or release harmful substances due to excessive temperature, and ensure water quality safety. For sealing technology, the pump used in water boilers adopts specially designed high-temperature seals, such as fluororubber seals. Fluororubber has excellent high-temperature resistance, aging resistance and chemical corrosion resistance, can maintain good sealing performance in high-temperature environments, and effectively prevent hot water leakage. At the same time, in the design of the sealing structure, multiple seals or labyrinth seals are adopted to further enhance the sealing effect and avoid equipment failures and safety hazards caused by seal failure.

2. Impact on Boiling Water Quality and Supply Efficiency

The flow regulation of the pump has a direct and important impact on the uniformity of boiling water temperature. During the operation of the water boiler, the water flow rate and heating power need to maintain a reasonable match. If the flow rate of the pump is too large, the residence time of water in the heating chamber is too short, which will lead to insufficient heating of the water, resulting in low water temperature; on the contrary, if the flow rate is too small, the residence time of water in the heating chamber is too long, which may cause the water to be overheated, not only wasting energy but also possibly affecting the taste and quality of the boiling water. Through precise flow regulation, it can ensure that the water is heated appropriately in the heating chamber, so that every drop of water can reach the set temperature, thus ensuring the uniformity of the boiling water temperature. For example, when the water boiler is in the low-flow water supply state, the pump will automatically reduce the flow rate, and the heating power will also be reduced accordingly, so that the water has enough time to absorb heat in the heating chamber to reach the predetermined temperature; when in high-flow water supply, the pump will increase the flow rate, and the heating power will also increase to ensure rapid heating and maintain stable water temperature.

High-efficiency pumps can significantly improve the water production speed and energy-saving effect of the water boiler. High-efficiency pumps usually adopt advanced motor technology and fluid dynamics design, which can generate greater flow and head under the same power input. In water boilers, high-efficiency pumps can quickly deliver cold water to the heating chamber and discharge hot water rapidly after heating, which greatly shortens the time from startup to producing boiling water, improves the water production speed, and meets users' demand for quickly obtaining boiling water. At the same time, high-efficiency pumps have higher energy conversion efficiency and can effectively reduce energy loss during operation. Compared with traditional low-efficiency pumps, under the same working time and water output, high-efficiency pumps consume less electricity, thus reducing the operating cost of the water boiler and achieving the purpose of energy saving. For example, high-efficiency pumps using brushless DC motors have a motor efficiency of more than 85%, which is much higher than that of traditional asynchronous motors, and can significantly reduce energy waste, in line with the current development trend of energy conservation and environmental protection.

3. Case Studies: Pump Application Cases in Commercial and Household Water Boilers

Commercial large-scale water boilers usually need to meet the concentrated water demand of a large number of people, so they have higher requirements for pump performance. Taking a large water boiler of a well-known commercial kitchen equipment brand as an example, it uses a high-power brushless DC food-grade water pump. The rated flow rate of this pump can reach 50L/min, and the head is 30m, which can deliver a large amount of water in a short time to meet the water demand during peak hours. In terms of materials, the pump body is made of 316L stainless steel, which has strong corrosion resistance and high-temperature resistance, and can adapt to the long-term high-temperature and high-frequency working environment of commercial water boilers. In addition, the pump is equipped with an intelligent control system, which can automatically adjust the speed according to changes in water consumption to achieve energy-saving operation. At the same time, it has perfect protection functions, such as overheating protection and overcurrent protection, which can effectively avoid pump damage caused by abnormal conditions and improve the reliability and service life of commercial water boilers.

Household small water boilers pay more attention to compactness and efficiency in pump selection. A small water boiler of a mainstream household appliance brand uses a micro brushless DC food-grade water pump. The pump is small in size, only 10cm in length and 5cm in diameter, and can be easily installed in the compact internal space of household water boilers. Its rated flow rate is 2L/min and the head is 5m, which can fully meet the daily water demand of families. In terms of efficiency, the motor efficiency of the pump is as high as 90%, and it consumes less electricity during operation, reflecting the characteristics of high efficiency and energy saving. In terms of materials, the parts in contact with water are made of food-grade PP plastic, which meets food safety standards and ensures pure water quality. Moreover, the pump operates with extremely low noise, less than 40 decibels, which will not interfere with family life. Its design also takes maintenance into consideration, with a simple structure and easy disassembly, facilitating users' daily cleaning and maintenance. This compact and efficient pump provides stable and reliable power support for household small water boilers and improves the user experience of the product.

Technical Requirements and Standards for Food-grade Pumps

1. Material Requirements

1.1 Selection of Materials in Contact with Food

1.1.1 Characteristics and applications of plastic materials that meet food hygiene and safety standards (such as PP, PE, etc.)

In the parts of food-grade pumps that come into contact with food, the selection of plastic materials is crucial. PP (polypropylene) has excellent chemical resistance and can resist the erosion of various acids and alkalis, which makes it perform well in juicers that transport acidic liquids such as fruit juices. At the same time, PP has good heat resistance and can maintain stable performance in higher temperature environments, making it suitable for use in home appliances with certain temperature requirements. Its surface is smooth, not easy to retain food residues, easy to clean, and reduces the risk of bacterial growth.

PE (polyethylene) has good flexibility and low-temperature resistance, and is not easy to embrittle in low-temperature environments. In water dispensers and other equipment that need to transport cold water, PE materials can well adapt to the working environment. Moreover, PE is non-toxic and tasteless, meets the safety standards for food contact materials, and will not pollute the transported liquid. In practical applications, plastic materials such as PP or PE can be reasonably selected according to the working conditions of different household appliances and the characteristics of the transported liquid to ensure the safe and reliable operation of food-grade pumps.

1.1.2 Advantages of stainless steel materials (such as 304, 316L, etc.) in food-grade pumps

304 stainless steel is one of the commonly used materials in food-grade pumps. It has good corrosion resistance and can resist the erosion of water, steam, weak acids and other substances commonly found in daily food processing and household appliance use. It has excellent mechanical properties and high strength, can withstand certain pressure and wear, and prolongs the service life of the pump. The surface of 304 stainless steel is smooth, easy to clean and disinfect, meets food hygiene requirements, and is widely used in coffee machines, dishwashers and other household appliances.

316L stainless steel further improves the corrosion resistance on the basis of 304 stainless steel, especially has stronger tolerance to chloride ions. In some dishwashers that may come into contact with chlorine-containing detergents, 316L stainless steel can better resist corrosion and ensure the long-term stable operation of the pump. In addition, 316L stainless steel also has better high-temperature strength and oxidation resistance, and is suitable for household appliances working in high-te household appliances working in high-temperature environments. Although the cost of 316L stainless steel is relatively high, its advantages are obvious in occasions with extremely high corrosion resistance requirements, and it can provide more reliable protection for food-grade pumps.

1.2 Corrosion Resistance and Sanitation of Materials

1.2.1 Performance of different materials in corrosive environments such as acid and alkali

Different materials have great differences in performance in corrosive environments such as acid and alkali. For plastic materials, PP is stable in acidic environments, but may swell to a certain extent in strong alkaline environments; PE has good resistance to both acid and alkali, but may also be affected under high-temperature and strong alkaline conditions.

Among stainless steel materials, 304 stainless steel can maintain good corrosion resistance in weakly acidic and weakly alkaline environments, but may corrode in strong acid or strong alkaline environments. However, due to the addition of molybdenum, 316L stainless steel has significantly improved corrosion resistance and can maintain good performance in strong acid, strong alkali and chloride-containing environments.

In practical applications, it is necessary to select appropriate materials according to the acid-base properties of the liquid in contact with the food-grade pump. For example, when transporting fruit juices with strong acidity, 316L stainless steel or PP material with good acid resistance should be selected; in dishwashers that come into contact with strong alkaline detergents, 316L stainless steel is a better choice to ensure that the pump can work stably for a long time in corrosive environments.

1.2.2 Impact of material surface treatment on preventing bacterial growth and cleaning convenience

Material surface treatment has a direct impact on preventing bacterial growth and improving cleaning convenience. For plastic materials, special surface treatment processes, such as polishing, can make the surface smoother, reducing the chance of liquid residue and bacterial adhesion. The smooth surface makes the cleaning process easier, and only simple wiping or rinsing can remove surface dirt, reducing cleaning costs and difficulties.

Good material surface treatment can not only ensure the hygienic safety of food-grade pumps, but also prolong the service life of the pumps and improve the operating efficiency of the equipment, which is of great significance for the application of food-grade pumps in various household appliances.

2. Sanitary Design Standards

2.1 Principle of Dead-angle-free Design

2.1.1 How the pump body structure design avoids liquid residue and dirt accumulation

The dead-angle-free design of the pump body structure is the key to avoiding liquid residue and dirt accumulation. In the design process, streamline internal structures should be adopted as much as possible to reduce parts that are prone to liquid retention, such as right angles, protrusions and depressions. For example, the interior of the pump cavity should transition smoothly to avoid steps and gaps, so that the liquid can flow smoothly and reduce residue.

The design of the impeller also needs to comply with the principle of no dead angles. Its blade shape should be optimized to ensure that the liquid can be fully discharged during rotation, avoiding liquid residue at the root of the blade and the hub. At the same time, the connection part of the pump inlet and outlet should adopt a smooth transition design to reduce liquid retention at the connection.

In addition, the sealing structure of the pump cannot be ignored. A suitable sealing method, such as mechanical seal, should be adopted to ensure the tight fit of the sealing surface and prevent liquid leakage and residue. Through reasonable pump body structure design, liquid residue and dirt accumulation can be minimized, and the hygienic performance of food-grade pumps can be guaranteed.

2.1.2 Design of detachable components for easy cleaning and maintenance

The design of detachable components provides great convenience for the cleaning and maintenance of food-grade pumps. In the design, key components of the pump, such as impellers, pump covers, and seals, should be designed in a detachable form, and the disassembly process should be simple and convenient without using complex tools.

In this way, during cleaning, these components can be easily disassembled for thorough cleaning and disinfection, ensuring that each component can be fully cleaned and avoiding dirt residue. At the same time, the detachable design also facilitates the inspection and maintenance of the internal structure of the pump. When components are worn or faulty, they can be replaced quickly, reducing equipment downtime and improving equipment utilization.

In terms of the connection method of detachable components, reliable and easy-to-operate structures, such as snap connections and threaded connections, should be adopted to ensure that components will not be damaged during disassembly and installation, and at the same time ensure the tightness of the connection to prevent liquid leakage.

2.2 Surface Finish and Cleanability

2.2.1 Impact of surface roughness on bacterial adhesion

Surface roughness is an important factor affecting bacterial adhesion. When the surface roughness of the pump body is high, there will be many tiny pits and protrusions on the surface, which become ideal places for bacteria to grow and reproduce. Bacteria can avoid the cleaning process in these pits, and after massive reproduction, biofilms will form, which not only affect the hygienic safety of the pump, but also may lead to equipment failure.

On the contrary, the pump body surface with low surface roughness and high finish has greatly reduced chances of bacterial adhesion. The smooth surface makes it difficult for bacteria to find attachment points, and even if a small amount of bacteria adhere, they are easily removed during cleaning. Therefore, controlling the surface roughness of the pump body at a low level is crucial for preventing bacterial adhesion and ensuring the hygienic performance of food-grade pumps.

Generally speaking, the roughness Ra value of the food-contact surface of food-grade pumps should be controlled within a certain range (usually Ra ≤ 0.8μm) to ensure that the surface has good finish and anti-bacterial adhesion ability.

2.2.2 Using special coatings or treatment processes to improve surface cleaning performance

To further improve the surface cleaning performance of food-grade pumps, special coatings or treatment processes can be used. For example, a food-grade non-stick coating, such as polytetrafluoroethylene (PTFE) coating, can be applied to the surface of the pump body. This coating has extremely low surface energy, making it difficult for liquids and dirt to adhere to its surface, which greatly improves the anti-adhesion performance and cleanability of the surface. During cleaning, only gentle wiping can remove surface dirt, reducing the cleaning time and the amount of cleaning agents used.

In addition, nano-coating technology is also an effective surface treatment method. Nano-coatings can form a nano-scale protective film on the surface of the pump body, making the surface smoother and at the same time having certain antibacterial properties. This protective film can inhibit the growth and reproduction of bacteria, improve the hygienic safety of the pump body surface, and enhance the wear resistance and corrosion resistance of the surface, prolonging the service life of the pump.

By adopting these special coatings or treatment processes, the surface cleaning performance of food-grade pumps can be significantly improved, ensuring that the pumps maintain a good hygienic state during long-term use.

3. Interpretation of Relevant International Standards

3.1 Specific requirements of FDA for food contact materials and products

The FDA (U.S. Food and Drug Administration) has strict requirements for food contact materials and products. According to FDA regulations, food contact materials must be safe, not pollute food, and not harm human health.

In terms of materials, the FDA has listed a list of substances allowed for food contact. For substances not included in the list, they need to be evaluated for safety and approved before use. Materials in food-grade pumps that come into contact with food, such as plastics and stainless steels, must comply with the relevant standards specified by the FDA.

In addition, the FDA requires that the amount of substances migrating from food contact materials to food under normal use conditions must not exceed the safety limit. For plastic materials, migration tests are required to ensure that their migrating substances meet the FDA's requirements. At the same time, the production process of food contact materials also needs to comply with Good Manufacturing Practice (GMP) to ensure product quality and safety.

3.2 Key clauses of EU 1935/2004 standard regarding food-grade pumps

EU 1935/2004 is the EU framework regulation on materials and articles in contact with food, which also has clear requirements for food-grade pumps. The standard stipulates that all materials and articles in contact with food shall not transfer their components to food under normal or foreseeable use conditions, which may endanger human health, nor cause unacceptable changes in food components or affect the sensory characteristics of food.

For food-grade pumps, the materials in contact with food must undergo strict evaluation and testing to ensure compliance with relevant safety standards. The standard also requires that food contact materials and articles should have appropriate labeling for traceability and supervision. In the production process, manufacturers need to establish an effective quality management system to ensure that products meet the requirements of EU 1935/2004 standard. At the same time, the standard also emphasizes the evaluation and approval procedures for new materials and technologies to adapt to the developing food contact materials industry.

How to choose a suitable food grade pump?

1. Flow and head requirements for food grade pumps

Flow rate and head are core technical parameters when selecting a food - grade pump, directly determining whether the pump can be adapted to the working scenario of specific household appliance products. For manufacturers of household appliances such as juicers, dishwashers, and coffee machines, accurately matching the flow rate and head can not only ensure stable product performance but also avoid energy waste and equipment loss.

1.1 Determine the flow requirements of food grade pumps based on application scenarios

Flow rate refers to the volume of liquid delivered by the pump per unit time, usually in liters per minute (L/min) or cubic meters per hour (m³/h). Different household appliance products have significantly different flow rate requirements for food - grade pumps due to functional differences.

The flow rate requirement of a "dishwasher" is relatively large, usually ranging from 8 to 15 L/min. A dishwasher needs to spray tableware with high - pressure water. Insufficient flow rate will lead to insufficient spraying force, affecting the cleaning effect. The flow rate of an embedded household dishwasher is generally 8 to 12 L/min, while that of a large commercial dishwasher can reach 12 to 15 L/min or even higher to improve cleaning efficiency, and it is also combined with higher pressure to ensure that oil stains and food residues are completely removed.

The flow rate requirement of a "coffee machine" varies depending on the brewing method. An espresso machine needs to precisely control a small flow rate, usually 0.5 to 2 L/min, to ensure sufficient extraction of coffee grounds under high pressure, so that the extracted coffee has richer crema and a more intense flavor. The flow rate of a drip coffee machine is slightly larger, generally 2 to 5 L/min, and the extraction process is completed by continuously wetting the coffee grounds with water flow.

The flow rate requirement of a "water dispenser" mainly depends on the water outlet speed, generally 1 to 3 L/min. The flow rate of a household water dispenser is usually 1 to 2 L/min, which can meet daily drinking needs; the flow rate of a commercial water dispenser will increase to 2 to 3 L/min due to high usage frequency and a large number of users, reducing the waiting time for water collection.

The flow rate of a "water purifier" is related to the filtration technology. The flow rate of an ultrafiltration water purifier is relatively large, generally 1 to 3 L/min; the flow rate of an RO reverse osmosis water purifier is usually small, 0.1 to 0.5 L/min, because it needs high pressure for filtration. Some RO water purifiers with a water storage bucket can make up for the insufficient flow rate by means of water storage, while the tankless RO water purifier can increase the flow rate to 0.5 to 1.5 L/min by improving the performance of the pump.

The flow rate requirement of a "water boiler" is usually 1 to 5 L/min. The flow rate of a small household water boiler is 1 to 2 L/min, and that of a commercial water boiler will reach 3 to 5 L/min to meet the needs of multiple people taking water at the same time, while ensuring that the outlet water temperature is stable near the boiling point.

When calculating the accurate flow rate, manufacturers need to consider their own product production scale or usage frequency. For manufacturers with a large production scale, if their products are for commercial scenarios, they need to calculate the flow rate according to the maximum load. For example, a commercial dishwasher needs to clean a large number of tableware every day, so a pump with a large flow rate should be selected; for products for household scenarios, an appropriate flow rate range should be selected based on the daily use frequency of families to avoid increased energy consumption due to excessive flow rate.

1.2 Head requirements and system resistance analysis of food grade pumps

Head refers to the vertical height that the pump can deliver liquid, in meters (m), which reflects the working capacity of the pump. In practical applications, the head is not simply the delivery height. It also needs to overcome various resistances in the system, so the actual required head is often higher than the theoretical delivery height.

In the scenario where the food - grade pump is applied to household appliances, the role of the head is crucial. Taking the coffee machine as an example, an espresso machine needs to deliver water to the coffee grounds under high pressure. At this time, the head of the pump needs to be high enough to ensure the extraction pressure, which generally requires a head of 8 to 15 m, so that high - quality espresso can be extracted. If the head is insufficient and the extraction pressure is not enough, the flavor and crema of the coffee will be affected.

System resistance is a key factor affecting head selection, mainly including pipeline length, pipe diameter, number of elbows, etc. The longer the pipeline length, the greater the frictional resistance between the liquid and the pipe wall during transportation, and the higher the required head. For example, in a large commercial kitchen, if the pipeline between the dishwasher and the water source is long, a pump with a higher head needs to be selected to overcome the pipeline resistance.

The size of the pipe diameter will also have an impact on system resistance. The smaller the pipe diameter, the greater the resistance when the liquid flows, because under the same flow rate, the flow velocity in the small - diameter pipeline is higher, and the friction loss is greater. Therefore, in the design of the pipeline system, an appropriate pipe diameter should be selected according to the flow rate to reduce system resistance and then reduce the requirement for the pump head.

The more the number of elbows, the more times the liquid changes the flow direction in the pipeline, and the greater the local resistance. Each elbow will cause a certain pressure loss, and the resistance accumulated by multiple elbows cannot be ignored. For example, in the pipeline system of a water purifier, due to the need to connect multiple filter elements, there are many elbows. When selecting the pump head, the resistance loss caused by these elbows must be considered.

To determine the appropriate head, it is necessary to accurately analyze the system resistance. First, calculate the theoretical delivery height, that is, the vertical distance that the liquid needs to be lifted; then, calculate the system resistance according to the actual parameters of the pipeline (length, pipe diameter, number of elbows, etc.) through relevant formulas or empirical data; finally, add the delivery height and system resistance to get the total required head, and select a food - grade pump with an appropriate head based on this. For example, in the pipeline system of a certain dishwasher, the delivery height is 1 m, the pipeline length is 5 m, the pipe diameter is 20 mm, and there are 3 elbows. After calculation, the system resistance is 3 m, so the total required head is at least 4 m. When selecting a pump, a product with a head of not less than 4 m should be selected to ensure the normal operation of the dishwasher.

2. Operating Environment Conditions of Food Grade Pumps

The operating environment of food grade pumps directly affects their performance, service life, and the safety and quality of the conveyed products. Different household appliances have significantly different working environments, so understanding the impact of these environmental conditions on pumps is an important prerequisite for selecting the right food grade pump.

2.1 Impact of Temperature and Humidity on Food Grade Pumps

Temperature and humidity are two key factors in the working environment of food grade pumps. They interact and jointly affect various components of the pump, especially in some special household appliances.

The challenges posed by high-temperature environments (such as in water boilers and dishwashers) to pump body materials and motor performance cannot be ignored. In water boilers, pumps need to frequently come into contact with high-temperature water close to the boiling point, which requires the parts of the pump body in contact with water to be made of high-temperature-resistant materials. Ordinary plastic materials are prone to softening, deformation, and even aging and cracking at high temperatures, which not only affects the sealing performance of the pump, leading to water leakage, but also may release harmful substances and contaminate the water quality. However, stainless steel materials such as 304 and 316L, as well as some special food-grade high-temperature-resistant plastics (such as PEEK, PPS, etc.), can maintain stable physical and chemical properties in high-temperature environments, ensuring the normal operation of the pump and the safety of the conveyed liquid. For motors, high-temperature environments will affect their insulation performance. The insulation materials of motor windings will accelerate aging under long-term high-temperature effects, reducing the insulation level, which may cause winding short circuits and lead to motor burnout. At the same time, high temperatures will also increase the temperature inside the motor, exceeding its allowable operating temperature range, reducing the efficiency and service life of the motor. Compared with traditional brushed motors, brushless DC motors have certain advantages in high-temperature resistance. They use high-performance insulation materials and optimized heat dissipation structures, which can better adapt to high-temperature environments. Even so, in high-temperature scenarios such as water boilers and dishwashers, additional heat dissipation designs for the motor are still required to ensure its stable operation.

The risk of corrosion to electrical components in high-humidity environments is also not to be underestimated, which is more common in household appliances such as dishwashers and water dispensers. High humidity will cause moisture in the air to adhere to the surface of electrical components of the pump, such as circuit boards, connectors, and motor terminals. This moisture will gradually penetrate into the components, causing oxidation and rusting of metal components, affecting the reliability of electrical connections, and may lead to problems such as poor contact and open circuits, making the pump unable to work normally. To cope with this risk, protective measures are crucial. In terms of design, electrical components with good sealing performance should be used, such as sealing circuit boards and connectors with sealing rings and sealants to prevent moisture intrusion. At the same time, choose corrosion-resistant metal materials to make components such as terminals, or perform plating treatment on them to enhance corrosion resistance. In addition, designing reasonable drainage and ventilation structures at the installation position of the pump to reduce the accumulation of moisture in the environment can also effectively reduce the risk of corrosion of electrical components by high humidity.

2.2 Liquid Properties and Corrosiveness of Food Grade Pumps

Food grade pumps convey a variety of liquids, many of which are corrosive to a certain extent. This directly affects the material selection and service life of the pump, which is particularly evident in household appliances such as juicers and dishwashers.

The requirements for material selection of pumps when conveying different liquids (such as acidic fruit juices and alkaline cleaning agents) are extremely high. Acidic fruit juices contain components such as fruit acids, which are corrosive to a certain extent. Long-term conveying will corrode pump bodies made of ordinary metal materials, leading to damage and leakage of the pump body. At the same time, the corroded metal ions may mix into the fruit juice, affecting the quality and safety of the fruit juice. Therefore, for food grade pumps used in juicers, the parts in contact with fruit juice should be made of materials with strong acid resistance, such as 316L stainless steel, which has better corrosion resistance than 304 stainless steel and can effectively resist the erosion of acidic liquids; food-grade engineering plastics such as PVDF (polyvinylidene fluoride) can also be used, which have excellent chemical corrosion resistance and temperature resistance. In dishwashers, alkaline cleaning agents are needed to remove oil stains, and alkaline cleaning agents are also corrosive to some metal materials. At this time, alkali-resistant plastic materials or specially treated metal materials can be selected to make relevant parts of the pump to ensure the normal operation and service life of the pump.

Evaluating the impact of liquid corrosiveness on the service life of the pump and formulating corresponding coping strategies are crucial to ensuring the long-term stable operation of the pump. The corrosiveness of liquids is affected by many factors, such as the concentration, temperature, and contact time of the liquid. Generally, the higher the concentration, the higher the temperature, and the longer the contact time, the stronger the corrosiveness of the liquid, and the greater the damage to the pump. To accurately evaluate its impact, relevant corrosion data manuals can be consulted to understand the corrosion rate of different materials in specific liquid environments, and simulation tests can also be conducted to observe the corrosion of the pump under actual working conditions. Based on the evaluation results, corresponding coping strategies can be adopted. In addition to selecting appropriate corrosion-resistant materials, the structural design of the pump can be optimized to reduce the residence time of liquid in the pump and reduce the possibility of corrosion; at the same time, strengthen the regular maintenance of the pump, timely clean up the residual liquid in the pump, check the corrosion of the pump body, and replace parts with signs of corrosion in a timely manner to extend the service life of the pump. In addition, for some highly corrosive application scenarios, anti-corrosion coatings can be applied to the surface of the pump to further enhance its corrosion resistance.

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117