The best car fan - A Comprehensive Guide

The main function of a car fan is to dissipate heat. It is an indispensable part of the cooling system for car engines (or electric motors), mainly for dissipating heat from the water tank and intercooler. The water tank is filled with warm coolant, which releases heat through contact with air, and the function of the fan is to accelerate this process, ensuring that the heat can be quickly and effectively dissipated. The types of car fans include clutch fans, radiator cooling fans, and air conditioning cooling fans. The clutch fan adjusts the working state of the fan by installing a fan clutch between the pulley and the fan wheel hub, and disengaging and engaging the clutch. This not only ensures the normal operating temperature of the engine, but also reduces power loss and fuel consumption. The automobile radiator assembly includes a water chamber, a water outlet chamber, and a radiator core. It is an indispensable and important component in the cooling system of automobile water-cooled engines, and is developing towards lightweight, efficient, and economical direction. The types of cooling fans include mechanical fans and electric fans, which increase the wind speed and volume passing through the radiator to improve its heat dissipation capacity. Fans are usually installed behind the radiator, positioned as close as possible to the center of the radiator core to enhance cooling effectiveness.

Want to learn more?

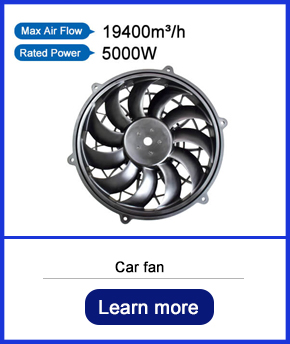

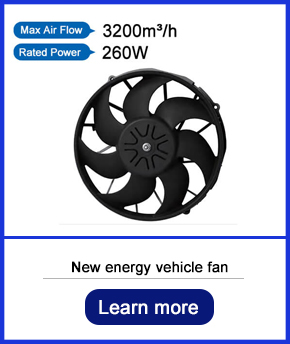

We can offer OEM/ODM service,car fan series by shenpeng:

|  |  |

The automobile cooling fan is a core component in the vehicle's thermal management system. In 2025, with the continuous evolution of automotive technology, its importance has become even more prominent. It actively inhales or discharges air to accelerate heat exchange, maintaining the vehicle's power system or battery pack within an appropriate operating temperature range. Whether it's the engine of a traditional fuel vehicle or the battery pack of a new energy vehicle, both rely on the cooling fan to achieve efficient heat dissipation, ensuring the vehicle's power performance, safety, and service life.

In the engine thermal management of traditional fuel vehicles in 2025, the cooling fan plays a crucial role as a "temperature regulator." When the engine is operating, the combustion process generates a large amount of heat. If the temperature is too high, it may cause piston expansion, a decrease in oil viscosity, increased component wear, and even serious engine failures such as "cylinder scoring" and "engine knocking." The cooling fan works in tandem with components like the radiator and water pump. When the engine water temperature rises to a set threshold, the fan starts. Through the rotation of its blades, it generates an air current, quickly dissipating the heat of the coolant in the radiator. The cooled coolant then recirculates into the engine to absorb excess heat. When the vehicle is moving at low speeds or idling, natural wind is often insufficient to meet the cooling needs, and the active heat dissipation function of the cooling fan becomes particularly important. However, when the vehicle is traveling at high speeds and natural wind can effectively dissipate heat, the fan will automatically stop or reduce its speed to reduce energy consumption. This dynamic adjustment ability ensures that the engine always operates within the optimal temperature range of 80 - 100°C in 2025, not only guaranteeing combustion efficiency but also reducing mechanical losses.

For electric vehicles in 2025, the role of the cooling fan in the battery thermal management system is even more refined and critical. The power battery is the core power source of an electric vehicle, and its performance, lifespan, and safety are closely related to temperature. Generally, the optimal operating temperature for lithium - ion batteries is 25 - 40°C. Excessive temperature can accelerate the internal chemical reactions of the battery, leading to capacity degradation and an increased risk of thermal runaway. Low temperature, on the other hand, reduces charging efficiency and discharge power, affecting the vehicle's range. The cooling fan, in cooperation with the liquid - cooling system or air - cooling channels, achieves precise temperature control of the battery pack. When the battery temperature rises due to charging, discharging, or high ambient temperatures, the fan accelerates air circulation, exhausting the heat from the battery surface or coolant outside the vehicle. When the ambient temperature is too low, in some vehicle models, the fan works with the heating device to circulate hot air inside the battery pack, raising the battery temperature. In addition, the fan can also balance the temperature differences among individual batteries in the battery pack, avoiding the problem of decreased battery consistency caused by local overheating or overcooling. This comprehensive temperature control not only extends the battery's service life but, more importantly, reduces safety hazards such as fires and explosions caused by abnormal temperatures in 2025, providing core support for the stable operation of electric vehicles.

Types and Applications of Automotive Fans

In 2025, as automotive technology continues to advance, car fans have evolved into diverse types tailored to different vehicle architectures and efficiency demands. From traditional mechanical fans to smart electric fans with precise control, each type offers unique advantages in terms of fuel economy, performance, and adaptability to modern vehicles like electric vehicles (EVs) and hybrids.

1. Mechanical vs. Electric Fans: Which Saves More Fuel?

Mechanical and electric fans represent two foundational fan technologies, with distinct operating principles that directly impact fuel efficiency— a critical factor in 2025’s landscape of stricter emissions regulations and rising fuel costs.

Mechanical fans, a long-standing design, are directly driven by the engine via a belt or pulley system. Their rotation speed is proportional to the engine’s RPM, meaning they spin faster as the engine revs higher, regardless of the actual cooling demand. This inherent linkage has advantages: mechanical fans are simple, durable, and cost-effective to manufacture, making them still relevant in some entry level fuel vehicles in 2025. However, their lack of independent control is a major drawback for fuel efficiency. At high speeds, when natural airflow through the radiator is sufficient, the mechanical fan continues to consume engine power, acting as a parasitic load that increases fuel consumption. Even at low speeds, if the engine is cold (e.g., during startup), the fan wastes energy by spinning unnecessarily.

Electric fans, by contrast, are powered by the vehicle’s electrical system (battery and alternator) and controlled by sensors or an ECU (Engine Control Unit). They operate independently of engine RPM, activating only when cooling is needed— such as when coolant temperatures rise above a threshold or during idle/low-speed driving. This on-demand operation eliminates the parasitic power loss of mechanical fans. In 2025, advancements in brushless motor technology have made electric fans more efficient than ever: they draw less electricity, respond faster to temperature changes, and can adjust their speed incrementally (rather than just on/off). For example, during highway driving, an electric fan may shut off entirely, relying on ram air for cooling, whereas a mechanical fan would still drain engine power. Studies show that in modern fuel vehicles, switching from a mechanical to an electric fan can improve fuel efficiency by 1-3%— a significant margin in 2025’s efficiency-focused market.

In the 2025 comparison, electric fans clearly outperform mechanical fans in fuel savings, especially in urban driving with frequent stops and starts, where their ability to avoid unnecessary operation shines. Mechanical fans persist mainly in legacy models or applications prioritizing low manufacturing costs over optimal efficiency.

2. Intelligent Fans with ECU Control (For EVs & Hybrids)

As EVs and hybrids dominate the 2025 market, intelligent fans with ECU (Electronic Control Unit) integration have become indispensable, offering precision cooling tailored to the unique demands of electrified powertrains.

Unlike traditional fans that respond solely to coolant temperature, intelligent fans are part of a interconnected thermal management system. The ECU collects real-time data from multiple sensors: battery temperature (in EVs), motor inverter heat, ambient temperature, and even driving conditions (e.g., fast charging, high-speed acceleration). Using this data, the ECU calculates the exact cooling requirement and adjusts the fan’s speed, airflow direction, or even activates supplementary cooling modes (e.g., Cooperate with liquid cooled radiators) to maintain optimal temperatures.

For EVs, battery thermal management is critical— lithium-ion batteries perform best at 25-40°C, with extreme temperatures reducing range, accelerating degradation, or risking thermal runaway. Intelligent fans work in tandem with liquid cooling loops: when the battery heats up during fast charging, the ECU ramps up fan speed to dissipate heat from the radiator, ensuring the coolant efficiently absorbs excess energy. Conversely, in cold climates, some systems reverse fan operation to recirculate warm air from the battery or cabin, pre-heating the pack to improve winter range.

In hybrids, which combine internal combustion engines and electric motors, intelligent fans balance dual cooling needs. The ECU prioritizes cooling the engine during high-load driving (e.g., highway acceleration) and shifts focus to the electric motor and battery during electric-only mode. This dynamic allocation minimizes energy waste, a key to maximizing hybrid efficiency in 2025.

2025’s intelligent fans also feature “predictive cooling.” Using AI algorithms, they anticipate heat spikes based on driving patterns (e.g., upcoming uphill climbs detected via GPS) and pre-activate cooling, preventing temperature overshoots and reducing energy consumption. Additionally, they integrate with vehicle-to-everything (V2X) technology, adjusting operation based on traffic or weather forecasts— for example, increasing fan readiness before entering a hot, congested area.

How Car Fans Work: From Airflow to Heat Dissipation

Car fans are unsung heroes in maintaining a vehicle’s thermal balance, quietly orchestrating a precise dance of airflow to keep engines, batteries, and critical components within safe operating temperatures. Whether in traditional gasoline cars, electric vehicles (EVs), or hybrids, the core mission remains the same: convert rotational energy into directed airflow, then use that airflow to expel excess heat. Let’s break down the process, from how fans generate movement to how that movement translates into effective heat dissipation.

Step 1: Generating Airflow – The Fan’s Mechanical Core

At its simplest, a car fan is a rotating assembly of blades designed to manipulate air movement. The key lies in aerodynamic blade design—2025 models feature advanced blade shapes, often optimized via computational fluid dynamics (CFD) simulations to maximize airflow while minimizing noise and energy use. When the fan spins, the blades create a pressure difference: the front of the blade (facing the direction of rotation) pushes air forward, while the back creates a low-pressure zone that draws in more air. This creates a steady stream of airflow, either pulling air into the system (intake fans) or pushing it out (exhaust fans), depending on the fan’s placement in the vehicle’s thermal system.

Mechanical fans, still found in some 2025 legacy vehicles, derive their rotational force directly from the engine via a belt or pulley system. Their speed is tied to engine RPM—faster engine rotation means faster fan spin. Electric fans, by contrast, use brushless motors powered by the vehicle’s battery. These motors are controlled by sensors or an ECU (Electronic Control Unit), allowing them to spin at variable speeds independent of engine activity, a feature critical for energy efficiency.

Step 2: Directing Airflow – Targeted Heat Exchange

Airflow alone isn’t enough—its path must be carefully directed to where heat is most concentrated. In traditional gasoline vehicles, the fan works with the radiator, a grid of small tubes filled with coolant that absorbs engine heat. The fan is positioned behind or in front of the radiator: when activated, it pulls cool ambient air through the radiator’s fins, which transfer heat from the hot coolant inside the tubes to the passing air. The now-heated air is then pushed out of the engine bay, while the cooled coolant circulates back to the engine to repeat the process.

In EVs and hybrids, the system is more complex, with multiple heat sources: batteries, electric motors, and inverters. Here, fans collaborate with liquid cooling loops or dedicated air channels. For example, battery packs in many 2025 EVs are encased in a sealed housing with coolant-filled pipes. The fan cools the radiator that dissipates heat from the coolant, ensuring the fluid can continuously absorb heat from the battery cells. Some EVs also use fans to circulate air within the battery pack itself, preventing hotspots by equalizing temperature across all cells.

Step 3: Regulating Airflow – Matching Demand to Need

The true sophistication of modern car fans lies in their ability to adjust airflow based on real-time cooling demands. This regulation prevents wasted energy and ensures components stay within their optimal temperature ranges.

Temperature Sensors: In both gasoline and electric vehicles, thermistors or thermocouples monitor temperatures (e.g., engine coolant, battery cells, motor windings). When readings exceed a set threshold (e.g., 90°C for engine coolant, 40°C for batteries), the sensors trigger the fan to activate or increase speed.

ECU Control: Intelligent fans in 2025 EVs and hybrids take regulation a step further. The ECU integrates data from sensors with driving conditions—for instance, detecting rapid acceleration (which heats the motor) or fast charging (which warms the battery)—and pre-emptively adjusts fan speed to prevent overheating before it occurs. This “predictive cooling” reduces energy waste compared to reactive systems.

Variable Speed Technology: Unlike older on/off fans, 2025 electric fans use pulse-width modulation (PWM) to adjust speed incrementally. A 30% speed setting might suffice for mild cooling during low engine load, while 100% speed is reserved for high-demand scenarios like towing or hot-weather driving. This precision minimizes power draw, boosting fuel efficiency in gasoline cars and extending range in EVs.

The End Result: Efficient Heat Dissipation

By generating, directing, and regulating airflow, car fans ensure that excess heat is safely and efficiently expelled from critical components. In gasoline vehicles, this protects the engine from damage and maintains fuel efficiency by keeping it in the optimal operating temperature range. In EVs, it preserves battery life, maximizes range, and mitigates the risk of thermal runaway. As 2025 vehicles grow more advanced—with higher-performance batteries and tighter packaging—fans will continue to evolve, becoming even more integral to balancing power, efficiency, and safety.

Energy-Saving & Noise Control Tech

1. PWM Speed Regulation (30% Energy Reduction)

In 2025, Pulse Width Modulation (PWM) speed regulation has emerged as a game - changer in automotive fan technology, delivering substantial energy savings. PWM works by rapidly switching the power supply to the fan motor on and off. The ratio of on - time to the total cycle time is called the duty cycle. By adjusting this duty cycle, the average voltage supplied to the motor can be precisely controlled, which in turn regulates the fan’s rotational speed.

For example, in a traditional automotive cooling fan setup without PWM, the fan often runs at a fixed speed (either on or at a single high - speed setting) when activated. This results in over - cooling during low - demand periods and unnecessary energy consumption. In contrast, a PWM - controlled fan can operate at a low speed when the engine or battery generates only a small amount of heat. As the temperature rises, the PWM system gradually increases the duty cycle, ramping up the fan speed to meet the cooling requirements.

Numerous real - world applications in 2025 have demonstrated the remarkable energy - saving potential of PWM. In electric vehicles, where battery range is a critical concern, PWM - regulated fans for battery thermal management systems can reduce energy consumption by up to 30%. This is because the fan only expends energy proportionate to the actual heat load. In traditional internal combustion engine vehicles, PWM - controlled radiator fans not only save fuel by reducing the engine’s parasitic load but also enhance overall cooling system efficiency. The technology has become so effective that it is now a standard feature in many high - end 2025 vehicle models and is quickly trickling down to more affordable segments.

2. Low - Noise Design (≤40dB for EV Cabins)

With the increasing prevalence of electric vehicles (EVs) in 2025, cabin noise has become a focal point for automotive engineers. Since EVs lack the engine noise that traditionally masked fan and other system noises, any unwanted sounds are more noticeable. To address this, manufacturers have developed advanced low - noise fan designs aimed at keeping cabin noise levels below 40dB, a threshold considered near - silent for human perception in a vehicle environment.

One of the key design elements for low - noise fans is aerodynamic optimization. Fan blades in 2025 are often shaped using computational fluid dynamics (CFD) simulations to minimize air turbulence. For instance, some blades are designed with serrated edges, similar to the feathers of an owl, which is known for its near - silent flight. These serrations break up the air as it passes over the blade, reducing the formation of noisy air vortices. Additionally, the pitch and angle of the blades are carefully calibrated to ensure smooth air movement while maintaining sufficient airflow for cooling or ventilation purposes.

Another aspect of low - noise design is the use of high - quality materials and precision - engineered components. Fan motors in 2025 are designed with improved bearings that reduce friction and vibration, two major sources of noise. The fan housing is also constructed with sound - dampening materials, which absorb and dissipate any remaining noise. In some cases, active noise cancellation technology is employed. This involves using microphones to detect fan - generated noise and then generating an opposite sound wave to cancel it out, further reducing the overall noise level in the EV cabin. As a result, passengers in 2025 EVs can enjoy a quieter, more comfortable ride, free from the distractions of fan - related noise.

How to Choose the Right Car Fan (By Vehicle Type)

Selecting the right car fan is not a one-size-fits-all decision. It depends heavily on the vehicle’s power type, as gasoline engines and electric vehicles (EVs) have distinct thermal management needs. The fan’s design, control logic, and performance must align with the specific demands of the powertrain to ensure efficient cooling, optimal energy use, and long-term reliability. Below is a breakdown tailored to each vehicle type.

1. For Gasoline Engines: Clutch Fans vs. Electric Fans

Gasoline engines generate heat through combustion, and their cooling systems rely on fans to regulate temperatures during varying driving conditions. The two primary options—clutch fans and electric fans—differ significantly in how they operate, making them better suited for specific scenarios.

Clutch fans are a traditional choice, favored for their simplicity and durability. They connect directly to the engine via a belt, meaning their speed is linked to the engine’s revolutions per minute (RPM). A temperature-sensitive clutch mechanism adjusts their effectiveness: when the engine is cold, the clutch slips, allowing the fan to spin slowly and conserve energy; as temperatures rise, the clutch engages, locking the fan to the engine’s rotation for maximum airflow. This design requires no external power source, making it ideal for older vehicles, heavy-duty trucks, or models used in harsh environments (e.g., dusty construction sites or off-road terrain). Clutch fans are also cost-effective to manufacture and maintain, with fewer components prone to failure. However, their reliance on engine RPM limits precision—at high speeds, they may continue spinning even when cooling demands are low, wasting a small amount of engine power and slightly reducing fuel efficiency.

Electric fans, by contrast, are the modern standard for most gasoline-powered cars, especially those with advanced engines like turbocharged or direct-injection models. They are powered by the vehicle’s electrical system and controlled by the ECU (Electronic Control Unit), which adjusts their speed based on real-time temperature data from sensors. This independence from engine RPM allows for precise regulation: electric fans can run at full speed during idling (when natural airflow is minimal) and shut off entirely at highway speeds (when wind alone suffices). Studies show they reduce fuel consumption by 1-3% compared to clutch fans, a benefit amplified in stop-and-go city driving. Electric fans also offer greater flexibility in placement, enabling engineers to optimize airflow around the radiator for better cooling efficiency. The tradeoff is higher upfront complexity—they depend on reliable motors and wiring—and slightly higher maintenance costs if components fail. They are best suited for newer vehicles where fuel efficiency and engine performance are priorities.

In summary: Choose a clutch fan for older, rugged, or low-maintenance vehicles. Opt for an electric fan if you drive a modern gasoline car and value fuel savings and precise cooling.

2. For EVs: Battery Cooling Fans (Must-Have Features)

In electric vehicles, the battery pack is the heart of the powertrain, and its performance, lifespan, and safety hinge on maintaining stable temperatures (typically 25–40°C). Battery cooling fans are critical to this process, but not all fans are equal. The best options include these must-have features:

1) Precise Speed Control

Lithium-ion batteries are sensitive to temperature fluctuations—even a 5°C difference between cells can degrade performance over time. A quality cooling fan should offer stepless speed adjustment (0–100%) controlled by the ECU, which uses data from dozens of battery sensors to match airflow to heat output. For example, during fast charging, the fan should ramp up instantly to dissipate excess heat; in cold weather, it can work with heating systems to circulate warm air and precondition the battery.

2) Uniform Air Distribution

Battery packs contain hundreds of individual cells, and uneven cooling can create “hotspots” that risk thermal runaway. The fan’s design—including blade angle, duct shape, and even multi-fan setups—must ensure airflow reaches every cell. Advanced models use computational fluid dynamics (CFD) to optimize airflow paths, keeping temperature variation across the pack below 3°C.

3) Low Power Consumption & Durability

EV range depends on efficient energy use, so the fan should minimize power draw (e.g., <5W in standby mode) while delivering sufficient airflow. It should also withstand harsh conditions: look for IP6K9K certification to resist dust and water, ensuring reliability in rain, snow, or high humidity. Brushless motors are preferred for their long lifespan and low energy loss.

4) Quiet Operation

EVs have little engine noise to mask fan sounds, so excessive noise can harm comfort. Top-tier fans use acoustic engineering—such as aerodynamic blades and vibration-dampening mounts—to keep noise below 40dB (equivalent to a quiet library). This ensures a peaceful cabin even during heavy cooling.

5) Integration with Thermal Systems

The best battery cooling fans work seamlessly with the EV’s broader thermal management system. They should coordinate with liquid cooling loops (activating when fluid temperatures rise) and HVAC systems (using cabin heat to warm the battery in cold weather). Some 2025 models even integrate with V2X (Vehicle-to-Everything) technology, predicting cooling needs based on upcoming driving routes (e.g., pre-cooling before a steep climb).

When choosing a battery cooling fan for an EV, prioritize these features to protect your battery’s health, maximize range, and ensure safe operation.

The performance of automotive fans is influenced by various factors, including material selection, design structure, working environment, and control technology. In terms of materials, blades need to have high strength, heat resistance, and corrosion resistance, while bearings and sealing materials are related to smooth rotation and durability. In terms of design, the shape, quantity, fan diameter, and speed of the blades all affect the air flow efficiency and noise level. The temperature, humidity, and dust impurities in the work environment pose challenges to the cooling and durability of fans. The application of intelligent control technology, through real-time monitoring and adjustment of fan speed, achieves precise cooling and energy-saving noise reduction. In summary, optimizing the performance of automotive fans requires comprehensive consideration of materials, design, environment, and control technology to meet the complex and changing working conditions, and promote the development of fan technology towards higher efficiency, environmental protection, and intelligence. MORE>>

The intelligent car fan control system integrates advanced technologies such as the Internet of Things, sensors, big data analysis, and AI algorithms, achieving efficient and intelligent management of car cooling. The system monitors the temperature, humidity and other parameters of key parts of the vehicle in real time, and uses preset algorithms for precise control, achieving automatic adjustment of fan speed, on time and working mode, effectively improving heat dissipation efficiency and energy efficiency.

This system has advantages such as precise temperature control, energy conservation and emission reduction, improved comfort, fault diagnosis and warning, and personalized settings. In the field of electric vehicles, optimizing heat dissipation efficiency is particularly important for improving driving range. At the same time, the system also has the ability to self learn and continuously optimize control strategies to cope with complex and changing driving environments.

Looking ahead to the future, intelligent automotive fan control systems will exhibit trends such as deep integration and intelligence, adaptive learning capabilities, cross-border fusion innovation, and standardized and modular design. These developments will further enhance the energy efficiency and environmental friendliness of the system, and promote the popularization of technology and cooperation in the industrial chain. MORE>>

Application of New Materials in Automotive Fans

The application of new materials in the manufacturing of automotive fans brings new opportunities to the automotive industry. Modified polypropylene (PP) material has become an ideal choice for automotive fan manufacturing due to its high temperature resistance, lightweight, high strength, economy, and ease of processing. Composite material fan blades further enhance fan performance by being lightweight, high-strength, earthquake resistant, and corrosion-resistant. At the same time, the trend towards intelligence and networking of automotive electronic fans provides new avenues for improving fan performance and optimizing heat dissipation efficiency. The application of these new materials and technologies not only improves the performance and quality of automotive fans, but also provides strong support for innovation and development in the automotive industry. In the future, with the continuous advancement of technology and changes in market demand, the performance and quality of automotive fans will be further improved. MORE>>

Car fans play a central role in the engine cooling system, which is crucial for maintaining the optimal operating temperature of the engine. The cooling system consists of components such as coolant, radiator, water pump, thermostat, and fan, which work together to dissipate engine heat to the environment and ensure stable power output of the engine. Car fans accelerate the cooling process of the coolant by forcibly dissipating heat, especially working efficiently under extreme conditions to prevent engine overheating.

Modern car fans are often equipped with electronic control units (ECUs) for intelligent management. Based on comprehensive judgment of multiple parameters, precise control of fan operation is achieved, balancing energy consumption and heat dissipation effect. Fans are divided into mechanical and electric types, with electric fans gradually becoming popular due to their independent control, flexibility, and high efficiency. High end models adopt multi fan design and advanced heat dissipation materials to improve cooling efficiency.

Car fan failure can seriously affect engine performance and even cause mechanical damage, so regular inspection and maintenance are crucial. With the development of automotive technology, electric fans have become the mainstream trend, providing more reliable protection for engines and ensuring stable operation of vehicles under various working conditions. As a key component of the cooling system, the performance of the car fan directly affects the health and safety of the engine. MORE>>

The Importance of Automotive Fans Reflects

1. Protecting the engine: As mentioned earlier, the primary task of a car fan is to ensure that the engine is at the appropriate operating temperature, prevent mechanical failures caused by overheating, and thus extend the engine's service life.

2. Improving fuel economy: Overheating of the engine can affect the combustion efficiency of fuel, leading to an increase in fuel consumption. The effective operation of car fans can maintain the normal temperature of the engine, indirectly improving fuel economy.

3. Ensuring driving safety: In extreme weather conditions such as high temperatures or prolonged high-speed driving, the performance of the car fan directly affects the vehicle's ability to operate stably and continuously, thereby affecting driving safety.

4. Reduce maintenance costs: Regularly inspecting and maintaining car fans to ensure their proper functioning can prevent larger malfunctions caused by engine overheating, thereby reducing repair costs and parking time. MORE>>

Address:No.30, Dapu lndustrial Street, Changping, Dongguan, Guangdong, China

Tel: +86-186 7628 8117