How long can a mini water pump run continuously?

Published:2025-04-12

In the world of fluid handling, the question of how long a mini water pump can run continuously is of great significance, especially for applications in diverse fields such as new energy vehicles, household appliances (water heaters, dishwashers, coffee machines, water dispensers), smart toilets, water - heated mattresses, chillers, beauty and medical equipment, commercial air conditioners, energy - storage air conditioners, and heat pumps.

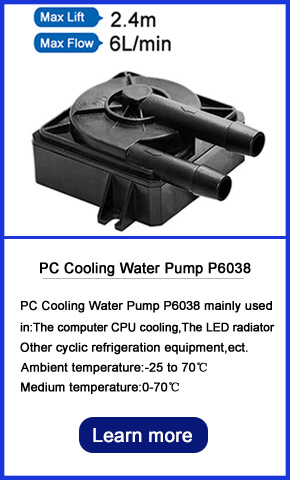

All standard Mini water pump by SHENPENG with lower price you will find here:

|  |  |

1. Motor and Bearing Design

The heart of a mini water pump is its motor. For a DC brushless motor, which is widely used in modern mini water pumps, it has several advantages that contribute to its continuous operation ability. The brushless design eliminates the wear and tear caused by mechanical brushes in traditional motors. This reduces the risk of sparking and mechanical failures associated with brush contact.

High - quality bearings are also crucial. Bearings in a well - designed mini water pump are engineered to handle the radial and axial forces generated during operation. For example, in applications like water - heated mattresses where the pump may need to run for extended periods during cold nights, the bearings are designed to have low friction and high durability. Premium ceramic or stainless - steel bearings can significantly extend the pump's continuous - running lifespan. In some high - end mini water pumps, the motor and bearing combination can enable the pump to run continuously for tens of thousands of hours.

2. Cooling and Heat Dissipation

During continuous operation, a mini water pump generates heat. Efficient cooling and heat dissipation mechanisms are essential to prevent overheating, which can lead to reduced performance and ultimately, pump failure. In applications such as new energy vehicles, where the pump may be used for battery cooling, the heat generated by the pump itself needs to be managed effectively.

Some mini water pumps are equipped with built - in heat sinks. These heat sinks increase the surface area through which heat can be dissipated to the surrounding environment. Additionally, in applications where the pump is in a closed - loop system, like in a chiller, the circulating fluid can also help carry away the heat generated by the pump. For instance, in a commercial air - conditioning system, the refrigerant - based cooling system not only cools the air but also helps in dissipating the heat from the mini water pump that circulates the coolant within the system. Well - designed cooling and heat - dissipation systems can ensure that the pump can run continuously under normal operating temperatures for long periods.

3. Fluid Properties and System Design

The properties of the fluid being pumped also play a role in determining how long a mini water pump can run continuously. If the fluid is corrosive, such as in some industrial - like applications where the pump might be used to circulate certain chemical - containing cooling fluids, the pump needs to be made of corrosion - resistant materials. For example, in a beauty and medical equipment where the pump may handle sterilized water or special cleaning solutions, the materials in contact with the fluid must be non - reactive.

The system design also matters. In a smart toilet, the water pressure and flow rate requirements are different from those in a large - scale commercial air - conditioning system. A properly designed system with the right pressure and flow control valves can ensure that the pump operates within its optimal performance range. If the pump is forced to work against excessive pressure or with a flow rate that is too high or too low for its design, it will experience additional stress, which can shorten its continuous - running time.

4. Quality of Manufacturing and Materials

Mini water pumps from reputable manufacturers that adhere to strict quality control standards are more likely to have a longer continuous - running lifespan. High - grade materials are used in the construction of the pump's housing, impeller, and other components. For example, the impeller, which is responsible for moving the fluid, is often made of high - strength polymers or corrosion - resistant metals. In a water heater, the pump's housing needs to be able to withstand high temperatures and the corrosive nature of hot water over time.

Manufacturing processes also impact the pump's quality. Precision - engineered components ensure a proper fit and reduced vibration during operation. Vibration can cause premature wear and tear on the pump's parts. A well - manufactured mini water pump, with high - quality materials and precise construction, can be expected to run continuously for extended periods, meeting the demands of various applications.

In conclusion, a well - designed and properly maintained mini water pump can run continuously for a very long time, often tens of thousands of hours. However, this is highly dependent on factors such as motor and bearing design, cooling and heat dissipation, fluid properties and system design, as well as the quality of manufacturing and materials. By carefully considering these aspects, users can ensure that their mini water pumps operate reliably and continuously in their specific applications.

- Distribution in Water Heater Mattresses: Why BLDC Pumps Ensure Uniform Heating

- How BLDC Pumps Ensure Precise Flow in Water Dispensers

- Why BLDC Pumps Are Essential for Smart Toilets

- The Critical Role of Automotive Electronic Water Pumps in New Energy Vehicle Battery Thermal Management

- Noise Control Technology for Smart Toilet Water Pumps: Enhancing Quiet Operation in Modern Bathrooms

- Unveiling the Working Principle of Automotive Electronic Water Valves

- Comparative Analysis of Liquid-Cooled Pumps vs. Air-Cooled Systems for EV Charging Stations

- Technical Application of Brushless DC Motors in Energy Storage Circulation Pumps

- Water Heater Pump: Efficiency Upgrade for Low-Voltage Systems

- How Dishwasher Water Pumps Enhance Cleaning Coverage Through Stable Operation?