The physical principle of water pump

Published:2020-12-23

Hydraulic machinery that uses power equipment and transmission devices or uses natural energy to raise water from low to high. It is widely used in farmland irrigation, drainage, agriculture and animal husbandry, industrial and mining enterprises, urban water supply, drainage, etc. The water pump used in farmland irrigation and drainage and agricultural production is called agricultural water pump, and it is one of the main components of farmland irrigation and drainage machinery.

According to different working principles, it can be divided into volumetric pumps and vane pumps.

Positive displacement pumps use changes in the volume of their working chambers to transfer energy, and mainly include piston pumps, plunger pumps, gear pumps, diaphragm pumps, and screw pumps.

Vane pumps use the interaction between the rotating blades and water to transfer energy, and there are centrifugal pumps, axial flow pumps and mixed flow pumps. The pump body of the submersible electric pump is a vane pump.

Other types of water pumps include jet pumps, water hammer pumps, internal combustion water pumps, etc., which work using the principles of jet water hammer and fuel deflagration respectively. Water turbine pump is a combination of water turbine and vane pump.

Among the above-mentioned types of pumps, the following types are more representative.

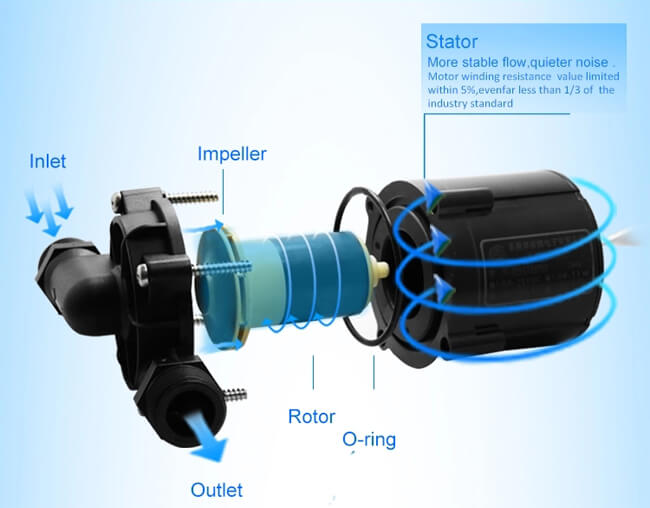

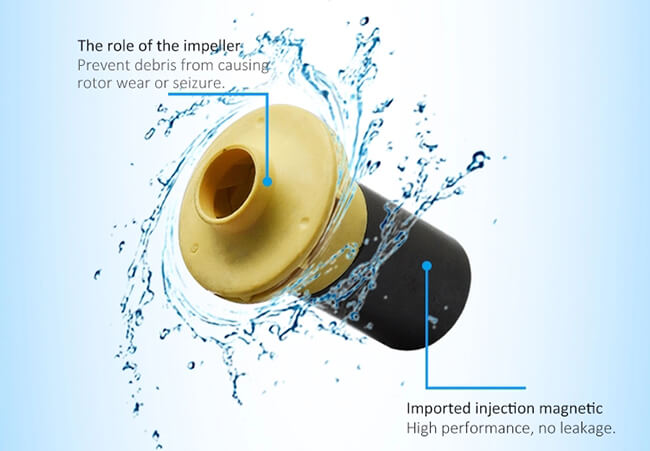

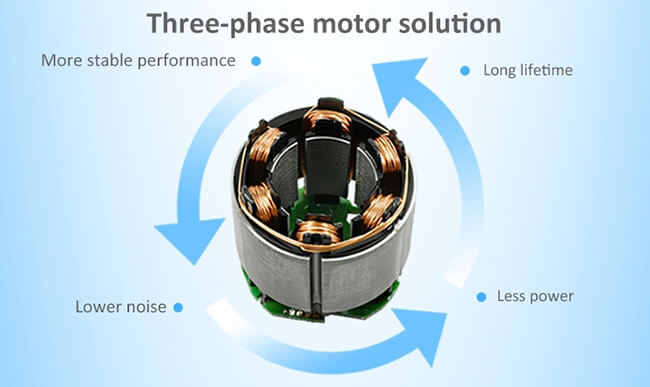

A centrifugal pump is a pump that uses centrifugal force to increase the pressure of water and make it flow. It is composed of pump casing, impeller, rotating shaft, etc. The power machine drives the rotating shaft, and the rotating shaft drives the impeller to rotate at a high speed in the pump casing. The water in the pump is forced to rotate with the impeller to generate centrifugal force. The centrifugal force forces the liquid to be thrown out from the periphery of the impeller, and the high-speed and high-pressure water flows out of the pump through the pump casing, and a low pressure is formed at the center of the impeller, thereby sucking in new water flow and forming a continuous water flow transportation. The impeller has blades that are curved in the opposite direction of rotation, and its structure types are closed, semi-closed and open. Most agricultural ones are closed impellers, and both sides of the blades are closed by discs. The pump body gradually expands into a volute shape along the direction of the outlet pipe. Water drawn from one side of the impeller is called a single-suction centrifugal pump, and drawn from both sides of the impeller is called a double-suction centrifugal pump. To increase the head, multiple impellers can be installed on the same shaft to become a multi-stage centrifugal pump. The water discharged from the previous impeller enters the water inlet of the next impeller, and then is discharged from the next impeller after being pressurized. Therefore, the more impellers, the higher the pressure. Some centrifugal pumps are equipped with a device that can automatically remove the air in the suction pipe and the pump body. There is no need to fill the pump body before starting. It is called a self-priming centrifugal pump, but its efficiency is often lower than that of ordinary centrifugal pumps.

Centrifugal pumps are the most widely used in farmland irrigation and drainage and water supply in agriculture and animal husbandry. It is mostly used in occasions with high lift and small flow. The head of the single-stage centrifugal pump is 5 to 125 meters, and the discharge flow is uniform, generally 6.3 to 400 meters per hour, and the efficiency can reach about 86 to 94%.

- Distribution in Water Heater Mattresses: Why BLDC Pumps Ensure Uniform Heating

- How BLDC Pumps Ensure Precise Flow in Water Dispensers

- Why BLDC Pumps Are Essential for Smart Toilets

- The Critical Role of Automotive Electronic Water Pumps in New Energy Vehicle Battery Thermal Management

- Noise Control Technology for Smart Toilet Water Pumps: Enhancing Quiet Operation in Modern Bathrooms

- Unveiling the Working Principle of Automotive Electronic Water Valves

- Comparative Analysis of Liquid-Cooled Pumps vs. Air-Cooled Systems for EV Charging Stations

- Technical Application of Brushless DC Motors in Energy Storage Circulation Pumps

- Water Heater Pump: Efficiency Upgrade for Low-Voltage Systems

- How Dishwasher Water Pumps Enhance Cleaning Coverage Through Stable Operation?